Kia Sportage: Components and Components Location | Description and Operation

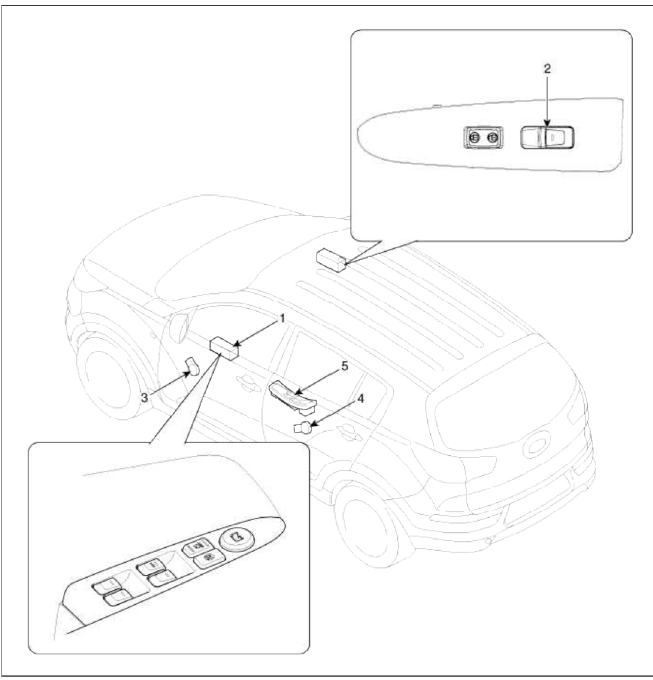

Component Location

- Driver power window main switch

- Passenger window switch

- Front window motor

- Rear window motor

- Rear window switch

Description and Operation

Operation

Function Of Safety Power Window

When all door (Front, Rear) power window auto-up switch is operated, safety function is activated.

1. Safety function condition.

When detect the force of 100N during the window using, window is reversed.

2. Length of window reversing (except holding the auto-up switch).

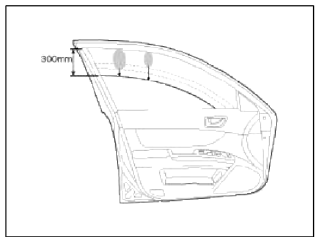

- When detect the jamming during the 4mm ~ 250mm from top of the door.

→ Window is reversed until 300mm from top of the door.

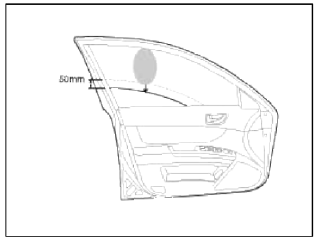

- When detect the jamming over the 250mm from top of the door.

→ Window is reversed until 50mm from jamming position.

→ Window is reversed 50mm or bottom position in case of 50mm reversing distance.

- When detect the jamming over 300mm from top of the door.

→ Window stops at reverse point.

3. Length of window reversing (holding the auto-up switch)

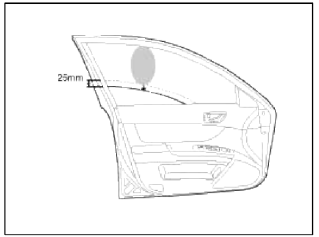

- When detect the jamming during holding the auto-up switch.

→ Window is reversed until 25mm from jamming position.

- Auto-up function is not available during the 5 seconds from above condition.

→ When holding the auto-up switch, window is operated as a manual-up function. (Safety function is not activated.)

- When detect the jamming during holding the auto-up switch again.

→ Window is reversed until 25mm from jamming position.

- When holding the auto-up switch after 5 seconds from above condition.

→ Window is reverse until 25mm from jamming position.

4. Safety function is not available area

Safety function is not available during the 4mm from top of the door.

Initializing Method Of The Safety Power Window

1. Position counter and position initialization

- Position counter

Window position counting is implemented by use of one Hall Effect sensor (HEF) connected to timer capture unit of the Controller with a resolution of 180º electrical.Even the battery was separated from the car, it must keep the window position information.

- Position initialization For position initialization, position counter detect the upper mechanical stop and lower mechanical Position.

Motor control unit (MCU) allow only Manual mode activity (without ASD Anti-Squeeze Detection algorithm) feature) before to be initialized.

Initialization means the condition to move the window system with full anti-pinch function and related functions by detecting the window travel distance (Upper/Lower mechanical limits).

Conditions for initialization are

- de-initialized position counter

- Power window switch Up activated

- block condition detected (no motor movement of more than 1 count during 1sec/ SW dependent)

Switch action with De-initialized condition:

- Up direction: Manual & Auto P/WDW sw input → manual mode;

- Down direction: Manual P/WDW sw input → manual mode, + Auto s/w input → auto mode

- Re-initialization

During re-initialization, position counter is set to "zero" at upper block position to compensate counting errors by software, mechanical tolerances or physics. Conditions for re-initialization are

- initialized position counter.

- window at upper block position (capture range EEPROM programmable)

- block condition detected (no motor movement of more than 1 count during 1sec/ SW dependent)

- De-initialization

The system initialization/calibration will be lost in the following cases:

- After parameter modification via diagnostic

- Wrong EEPROM checksum at ECU wake-up or power-on

- Movement outside predefined window stroke (above learned top position, below predefined bottom position)

- De-initialization after a defined number (EEPROM) of reversals without re-initialization in the upper seal (activation /de-activation controlled by EEPROM value). A window down movement or switching off the window lifter permission resets the reversal counter value (activation by EEPROM bit).

- De-initialization after a defined number of movements (EEPROM) without re-initialization in the upper seal (activation /de-activation controlled by EEPROM value)

- Special de-initialization procedure: The special window lifter de-initialization procedure works as follows:

- System is initialized

- Move window below soft-stop position (position EEPROM adjustable)

- Press MANU-down switch and keep it pressed

- Apply permission signal (serial-link = PIN 6) ON → OFF → ON within 2 seconds (time EEPROM adjustable)

- Soft stop function

In order to reduce noise and mechanical stress, the window movement is stopped under control of the ECU before the bottom position is reached.The clearance is 0 / +10 mm (at 11.5 V to 14.5 V).

To activate the soft bottom stop function, the top reference position and bottom reference position have to be initialized. Therefore, the window is lifted into the top position until the block condition is detected. This position is taken as top reference position.

Afterwards, the window is moved to the bottom position until the block condition is detected (mechanical stop). This position is taken as bottom reference position.

The bottom reference position is re-initialized:

- When window is operated down stalling from soft stop position

- Every "9" stops at soft stop position.

- Thermal protection

Thermal protection by software module is implemented to prevent from destruction of motor during overload condition. Motor temperature is estimated by integrating squared motor current as an estimate for heating power integral. When estimated motor temperature exceeds EEPROM programmable upper limit, motor is deactivated for fixed delay tune (default value = 30 sec.) Thermal shutdown during a window operation will not interrupt the operation due to safety reasons. - Operation tune limiter Maximal operation time of power window motor is limited to 15 sec (EEPROM programmable).

- Continuous reverse

Current Number of Continuous reverse of window is 5. With the below condition, this counter Will be initialized.

- IG OFF

- DOWN signal ON

- WINDOW CLOSE

READ NEXT:

Power Window Motor | Power Window Switch

Power Window Motor | Power Window Switch

Repair procedures

Inspection

Front Power Window Motor

1. Remove (-) negative battery terminal.

2. Remove the front door trim.

(Refer to the BD group - "Front door")

3. Disconnect

SEE MORE:

Windshield Glass

Windshield Glass

Components and Components Location

Components

Windshield side

molding

Windshield glass

Repair procedures

Replacement

Removal

CAUTION

Put on gloves to protect your hands.

Use seat covers to avoid damaging any surfaces

1. Remove the following items

Front pilla

Power brakes

Power brakes

Your vehicle has power-assisted brakes,

parking brake, and various braking systems

for safe driving.

Power brakes

Your vehicle has power-assisted brakes

that adjust automatically through normal

usage.

In the event that the power-assisted

brakes lose power because of a stalled

engine or so

Content

- Home

- Kia Sportage - Fifth generation (NQ5) - (2022-2026) - Owner's Manual

- Kia Sportage - Second generation (JEKM) (2005-2015) - Body Workshop Manual

- Kia Sportage Third generation (SL) - (2011-2016) - Service and Repair Manual

- Sitemap

- Top articles