Kia Sportage: Ignition System

Description and Operation

Description

Ignition timing is controlled by the electronic control ignition timing system. The standard reference ignition timing data for the engine operating conditions are preprogrammed in the memory of the ECM (Engine Control Module).

The engine operating conditions (speed, load, warm-up condition, etc.) are detected by the various sensors. Based on these sensor signals and the ignition timing data, signals to interrupt the primary current are sent to the ECM. The ignition coil is activated, and timing is controlled.

Repair procedures

On-vehicle Inspection

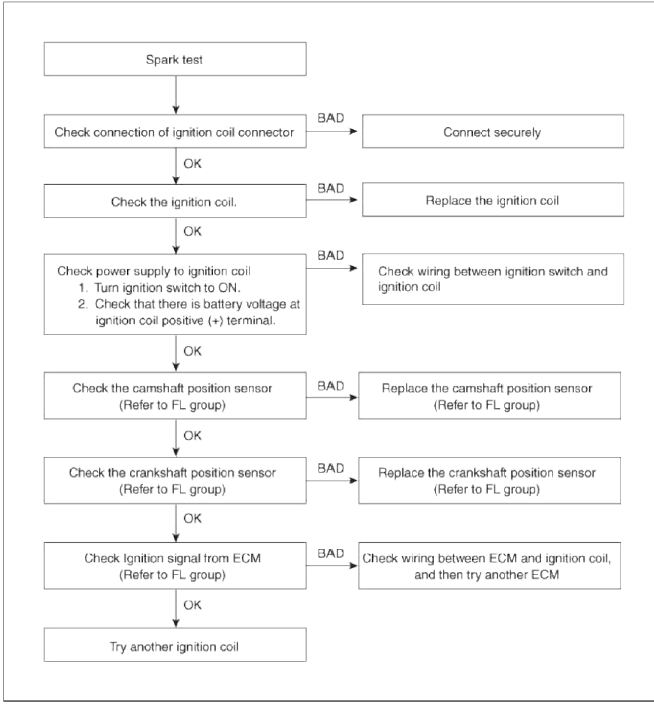

Spark Test

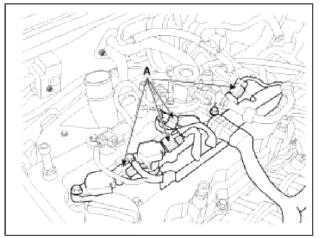

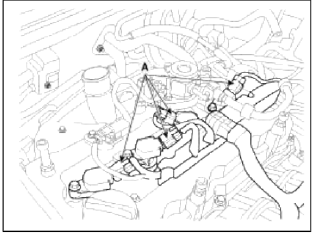

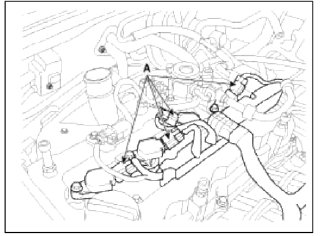

1. Disconnect the ignition coil connectors (A).

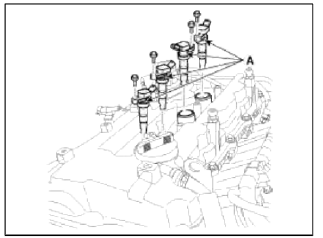

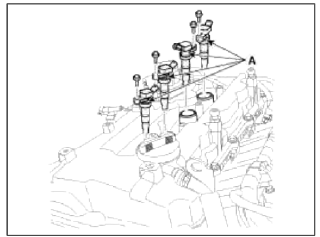

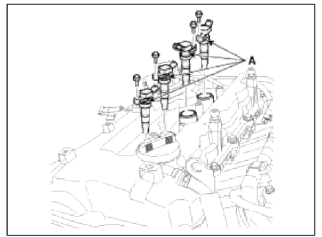

2. Remove the ignition coils (A).

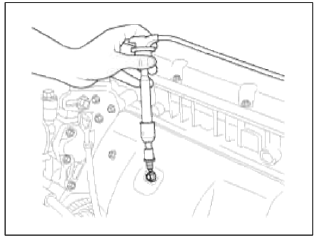

3. Using a spark plug socket, remove the spark plug.

4. Install the spark plug to the ignition coil.

5. Ground the spark plug to the engine.

6. Check if spark occurs while engine is being cranked.

NOTE

To prevent fuel being injected from injectors while the engine is being cranked, disconnect the injector connector.

Crank the engine for no more than 5 ~ 10 seconds.

7. Inspect all the spark plugs.

8. Using a spark plug socket, install the spark plug.

9. Install the ignition coil.

10. Reconnect the ignition coil connector

Inspect Spark Plug

1. Disconnect the ignition coil connectors (A).

2. Remove the ignition coils (A).

3. Using a spark plug socket, remove the spark plug.

CAUTION

Be careful that no contaminates enter through the spark plug holes.

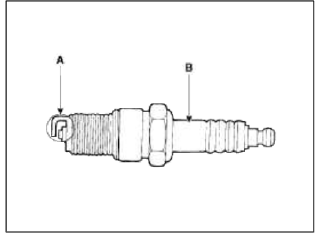

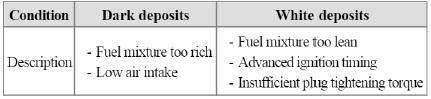

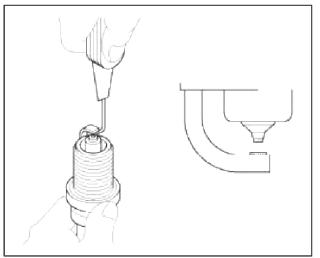

4. Inspect the electrodes (A) and ceramic insulator (B).

Inspection Of Electrodes

5. Check the electrode gap (A).

Standard

Unleaded : 1.0 ~ 1.1 mm (0.0394 ~ 0.0433 in.)

Inspection Ignition Coil

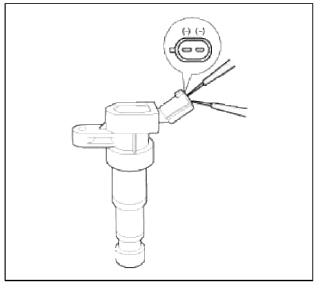

1. Measure the primary coil resistance between terminals (+) and (-).

Standard value: 0.62Ω +- 10%

Removal and Installation

1. Disconnect the ignition coil connectors (A).

2. Remove the ignition coils (A).

Tightening torque: 3.9 ~ 5.9N.m (0.4 ~ 0.6kgf.m, 2.9 ~ 4.3lb-ft)

3. Installation is the reverse of removal.

READ NEXT:

Description and Operation | Repair procedures

Description and Operation | Repair procedures

Description

The charging system includes a battery, an alternator with a built-in regulator, and the charging indicator light and wire.

The Alternator has built-in diodes, each rectifying AC

SEE MORE:

Reverse Parking Collision-Avoidance Assist operation

Reverse Parking Collision-Avoidance Assist operation

Operating conditions

After selecting Active assistance or

Warning Only from the Settings menu,

Reverse Parking Collision-Avoidance

Assist will turn on when the following

conditions are satisfied:

The liftgate is closed

The gear is shifted to R (Reverse)

Vehicle speed is below 6 mph (10

Driving on grades

Driving on grades

Reduce the speed and shift to a lower

gear before you start down a long or

steep downgrade. If you don't shift

down, you might have to use your

brakes so much that they would get hot

and no longer operate efficiently.

On a long uphill grade, shift down and

reduce your speed to around 45

Content

- Home

- Kia Sportage - Fifth generation (NQ5) - (2022-2026) - Owner's Manual

- Kia Sportage - Second generation (JEKM) (2005-2015) - Body Workshop Manual

- Kia Sportage Third generation (SL) - (2011-2016) - Service and Repair Manual

- Sitemap

- Top articles