Kia Sportage: Alignment

Repair procedures

Front Wheel Alignment

CAUTION

When using a commercially available computerized wheel alignment equipment to inspect the front wheel alignment, always position the vehicle on a level surface with the front wheels facing straight ahead.

Prior to inspection, make sure that the front suspension and steering system are in normal operating condition and that the tires are inflated to the specified pressure.

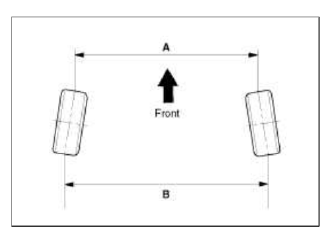

Toe

Ð’ - A > 0: Toe in (+)

Ð’ - A < 0: Toe out (-)

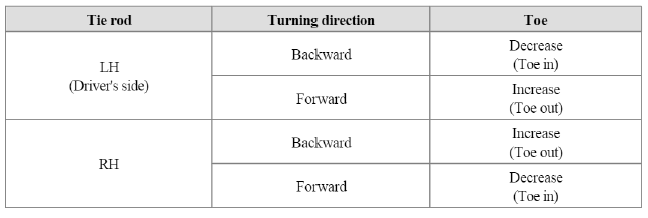

Toe adjustment

1. Loosen the tie rod end lock nut.

2. Remove the bellows clip to prevent the bellows from being twisted.

3. Adjust the toe by screwing or unscrewing the tie rod. Toe adjustment should be made by turning the right and left tie rods by the same amount.

Toe

Total: 0º+-0.2º

Individual: 0º+-0.1º

4. When completing the toe adjustment, install the bellows clip and tighten the tie rod end lock nut to specified torque.

Tightening torque : 49.0 ~ 53.9N.m (5.0 ~ 5.5kgf.m, 36.2 ~ 39.8lb-ft)

Camber and Caster

Camber and Caster are pre-set at the factory, so they do not need to be adjusted. If the camber and caster are not within the standard value, replace or repair the damaged parts and then inspect again.

Camber angle : -0.5º+-0.5º

Caster angle : 4.02 º +- 0.5º

Rear Wheel Alignment

CAUTION

When using a commercially available computerized wheel alignment equipment to inspect the rear wheel alignment, always position the vehicle on a level surface.

Prior to inspection, make sure that the rear suspension system is in normal operating condition and that the tires are inflated to the specified pressure.

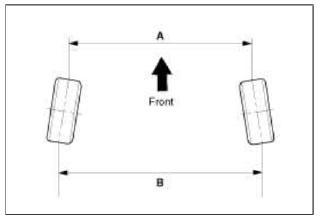

Toe

Ð’ - A > 0: Toe in (+)

Ð’ - A < 0: Toe out (-)

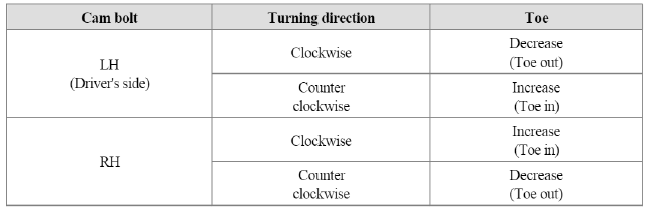

Toe adjustment

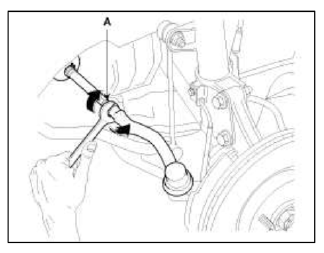

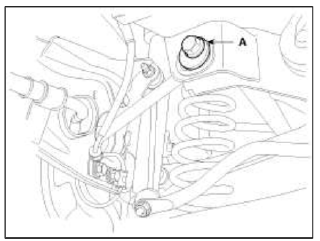

1. Loosen the nut holding the assist arm cam bolt (A).

2. Adjust rear toe by turning the rear assist arm cam bolt (A) clockwise or counter clockwise. Toe adjustment should be made by turning the right and left cam bolt by the same amount.

Toe

Total: 0.2º+-0.2º

Individual: 0.1º+-0.1º

3. When completing the toe adjustment, tighten the nut to specified torque.

Tightening torque: 107.9 ~ 117.7N.m (11.0 ~ 12.0kgf.m, 79.6 ~ 86.8lb-ft)

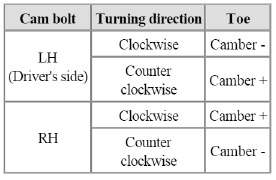

Camber

Adjust the camber by turning the cambolt of the rear lower arm.

Camber: -1.0º+-0.5º

READ NEXT:

Components and Components Location, Description and Operation

Components and Components Location, Description and Operation

Components and Components Location

Components Location

Receiver

TPMS Sensor

TPMS Sensor

TPMS Sensor

TPMS Sensor

Description and Operation

Description

TREAD Lamp

Tir

TPMS Sensor

TPMS Sensor

Description and Operation

Description

1. Mode

Configuration State

All sensors should be in the Low Line (Base) state.

In Low Line (Base) configuration, sensor transmissions occur e

SEE MORE:

Low tire pressure telltale

Low tire pressure telltale

Low tire pressure telltale

Low tire pressure position telltale

When the TPMS warning indicators are

appeared, one or more of your tires is

significantly under-inflated.

Low tire pressure

If the telltale illuminates, immediately

reduce your speed, avoid hard cornering

and anticipate

Inside rear view mirror

Inside rear view mirror

Mirrors

This vehicle is equipped with inside and

outside rear view mirrors to provide

views of objects behind the vehicle.

Inside rear view mirror

Adjust the rear view mirror so that the

center view through the rear window is

seen. Make this adjustment before you

start driving.

Do not pla

Content

- Home

- Kia Sportage - Fifth generation (NQ5) - (2022-2026) - Owner's Manual

- Kia Sportage - Second generation (JEKM) (2005-2015) - Body Workshop Manual

- Kia Sportage Third generation (SL) - (2011-2016) - Service and Repair Manual

- Sitemap

- Top articles