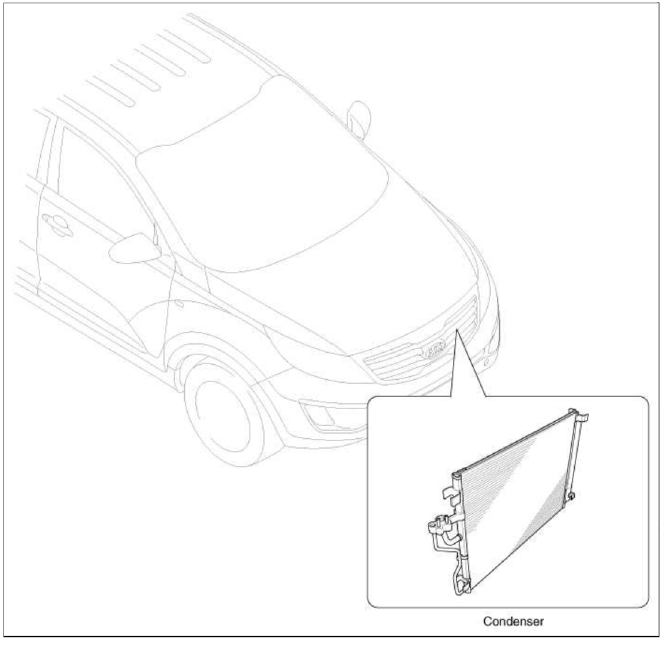

Kia Sportage: Condenser | Receiver-Drier

Components and Components Location

Component Location

Repair procedures

Inspection

1. Check the condenser fins for clogging and damage. If clogged, clean them with water, and blow them with compressed air. If bent, gently bend them using a screwdriver or pliers.

2. Check the condenser connections for leakage, and repair or replace it, if required.

Replacement

1. Recover the refrigerant with a recovery/ recycling/ charging station.

2. Disconnect the negative (-) battery terminal.

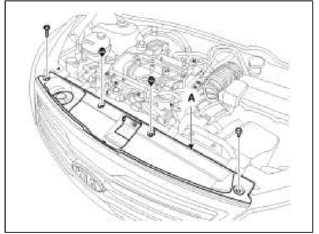

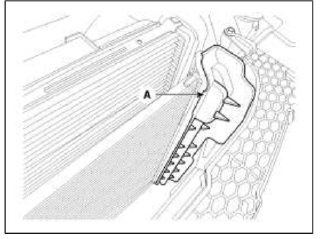

3. Remove the front bumper upper cover (A).

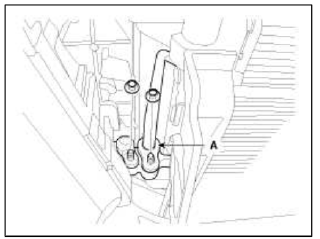

4. Remove the discharge line and liquid line (A) from the condenser.

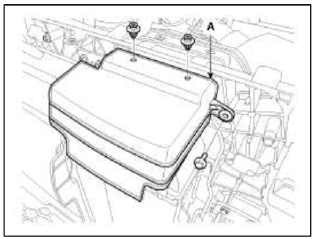

5. Remove the intercooler cover (A).

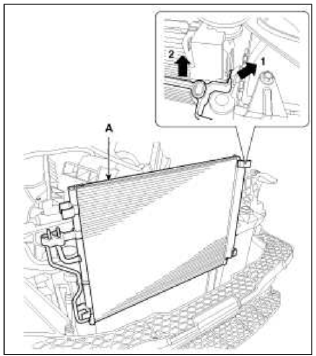

6. Remove the condenser side cover (A).

7. Remove the condenser (A) from radiator.

8. Install in the reverse order of removal, and note these items:

- If you're installing a new condenser, add refrigerant oil ND-OIL8.

- Replace the O-rings with new ones at each fitting, and apply a thin coat of refrigerant oil before installing them.

Be sure to use the right О-rings for R-134a to avoid leakage.

- Be careful not to damage the radiator and condenser fins when installing the condenser.

- Be sure to install the lower mount cushions of condenser securely into the holes.

- Charge the system, and test its performance.

Receiver-Drier

Repair procedures

Replacement

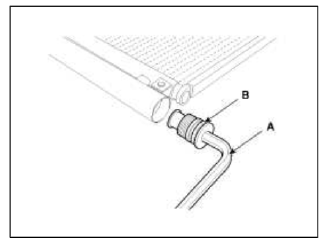

1. Remove the condenser, and then remove the bottom cap (B) with L wrench (A) from the condenser.

Tightening torque: 20~25N.m (2.0~2.5kgf.m, 14.5~18.2lb-ft)

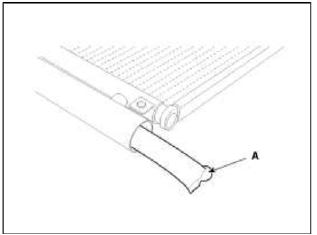

2. Remove the desiccant (A) from condenser using a long nose plier. Check for crumbled desiccant and clogged bottom cap filter.

3. Apply air conditioning compressor oil along the O-rings and threads of the new bottom cap.

4. Insert the new desiccant into the receiver drier tank. The desiccant must be sealed in vacuum before it is exposed to air for use.

5. Install the new bottom cap to the condenser.

NOTE

- Always replace the desiccant and bottom cap at the same time.

- Replace the О-rings with new ones at each fitting, and apply a thin coat of refrigerant oil before installing them. Be sure to use the right О-rings for R-134a to avoid leakage.

- Be careful not to damage the radiator and condenser tins when installing the condenser.

- Be sure to install the lower mount cushions of condenser securely into the holes.

- Charge the system, and test its performance

READ NEXT:

Ð/С Pressure Transducer | Evaporator Temperature Sensor

Ð/С Pressure Transducer | Evaporator Temperature Sensor

Components and Components Location

Component Location

Description and Operation

Description

Ð/С pressure transducer convert the pressure value of high pressure line into volta

SEE MORE:

Inspection - Repair procedures - Cylinder Head

Inspection - Repair procedures - Cylinder Head

Inspection

Cylinder Head

1. Inspect for flatness.

Using a precision straight edge and feeler gauge, measure the surface the

contacting the cylinder block and the

manifolds for warpage.

Flatness of cylinder head gasket surface

Standard : Less than 0.05mm (0.0019in.) for total area

Less tha

Specifications, Components and Components Location

Specifications, Components and Components Location

Specifications

Specifications

Display System

DVD Deck

Bluetooth

Storage Memory

Components and Components Location

Component Location

AVN (A/V & Navigation) head

unit

Tweeter speaker

External Amplifier

Roof antenna (GPS + SDARS +

Radio)

Front door sp

Content

- Home

- Kia Sportage - Fifth generation (NQ5) - (2022-2026) - Owner's Manual

- Kia Sportage - Second generation (JEKM) (2005-2015) - Body Workshop Manual

- Kia Sportage Third generation (SL) - (2011-2016) - Service and Repair Manual

- Sitemap

- Top articles