Kia Sportage: Repair procedures

Inspection

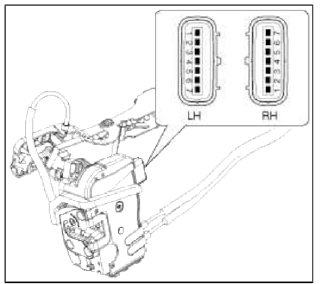

Front Door Lock Actuator Inspection

1. Remove the front door trim.

(Refer to the BD group - "Front door")

2. Remove the front door module.

3. Disconnect the 7P connector from the actuator.

4. Check actuator operation by connecting power and ground according to the table. To prevent damage to the actuator, apply battery voltage only momentarily.

[Central Lock]

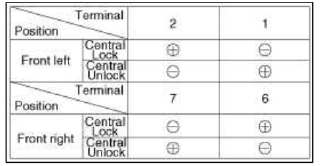

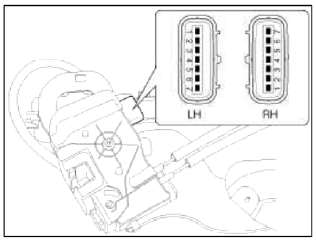

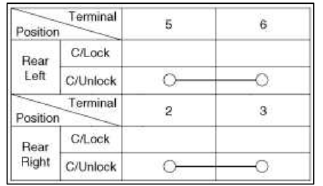

Rear Door Lock Actuator Inspection

1. Remove the rear door trim.

(Refer to the BD group - "Rear door")

2. Remove the rear door module.

З. Disconnect the 7P connector from the actuator.

4. Check actuator operation by connecting power and ground according to the table. To prevent damage to the actuator, apply battery voltage only momentarily.

[Central Lock]

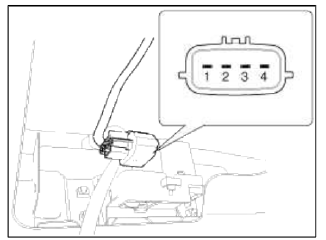

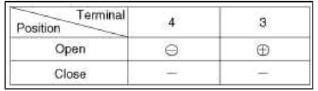

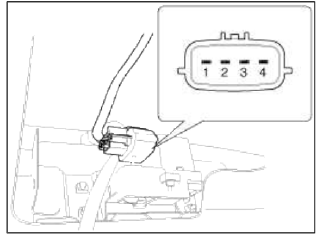

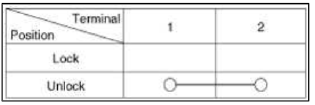

Tailgate Release Actuator Inspection

1. Remove the tailgate trim panel.

(Refer to the BD group - "Trunk lid")

2. Disconnect the 4P connector from the actuator.

3. Check actuator operation by connecting power and ground according to the table. To prevent damage to the actuator, apply battery voltage only momentarily.

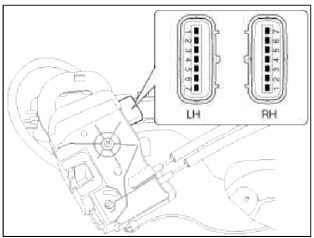

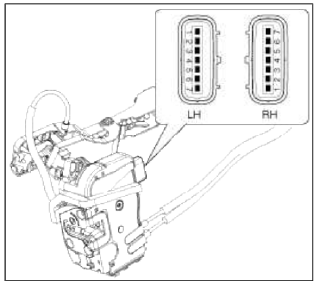

Front Door Lock Switch Inspection

1. Remove the front door trim panel.

(Refer to the BD group - "Front door")

2. Remove the front door module.

З. Disconnect the 7P connector from the actuator.

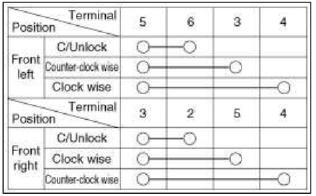

4. Check for continuity between the terminals in each switch position when inserting the key into the door according to the table.

[Central Lock]

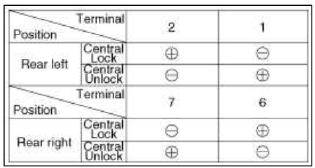

Rear Door Lock Switch Inspection

1. Remove the rear door trim panel.

(Refer to the BD group - "Rear door")

2. Remove the rear door module.

3. Disconnect the 7P connector from the actuator.

4. Check for continuity between the terminals in each switch position according to the table.

[Central Lock]

Tailgate Lid Open Switch Inspection

1. Remove the tailgate lid trim.

(Refer to the BD group - "Tailgate")

2. Disconnect the 4P connector from the actuator.

3. Check for continuity between the terminals in each switch position according to the table.

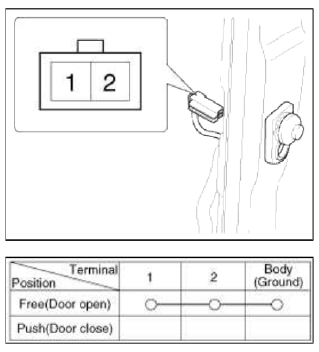

Door Switch Inspection

Remove the door switch and check for continuity between the terminals.

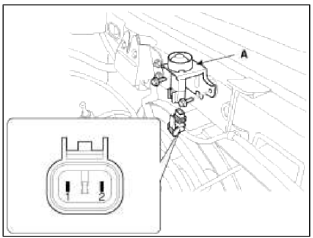

Hood Switch Inspection

1. Disconnect the connector from the hood switch (A).

2. Check for continuity between the terminals and ground according to the table.

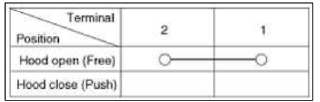

Burglar Horn Inspection

1. Remove the burglar horn (A) after removing 1 bolt and disconnect the 2P connector from the burglar horn.

2. Test the burglar horn by connecting battery power to the terminal 1 and ground the terminal 2.

3. The burglar horn should make a sound. If the burglar horn fails to make a sound replace it.

READ NEXT:

Transmitter

Transmitter

Repair procedures

Inspection

1. Check that the red light flickers when the door lock or unlock button is

pressed on the transmitter.

2. Remove the battery (A) and check voltage if the red light

Specifications, Schematic Diagrams, Description and Operation

Specifications, Schematic Diagrams, Description and Operation

Specifications

Specifications

Electrical Performance

Schematic Diagrams

Circuit Diagram

Description and Operation

Description

Body control module receives various input

SEE MORE:

Navigation-based Smart Cruise Control operation

Navigation-based Smart Cruise Control operation

Operating conditions

Navigation-based Smart Cruise Control

is ready to operate if all of the following

conditions are satisfied:

Smart Cruise Control is operating

Driving on main roads of highways (or

motorways)

WARNING

Navigation-based Smart Cruise Control

(NSCC) is a supplemental s

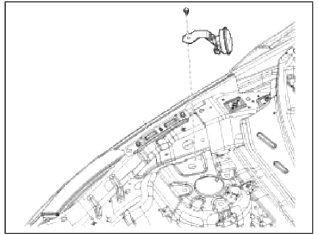

Components and Components Location | Rear Wiper Motor

Components and Components Location | Rear Wiper Motor

Component Location

Rear wiper motor assembly

Head cap

Rear wiper motor mounting bolt

Rear wiper motor mounting hole

Pad cap

Hexagonal nut

Cover

Rear wiper arm & blade

Rear wiper arm nut

Rear Wiper Motor

Repair procedures

Inspect

Content

- Home

- Kia Sportage - Fifth generation (NQ5) - (2022-2026) - Owner's Manual

- Kia Sportage - Second generation (JEKM) (2005-2015) - Body Workshop Manual

- Kia Sportage Third generation (SL) - (2011-2016) - Service and Repair Manual

- Sitemap

- Top articles