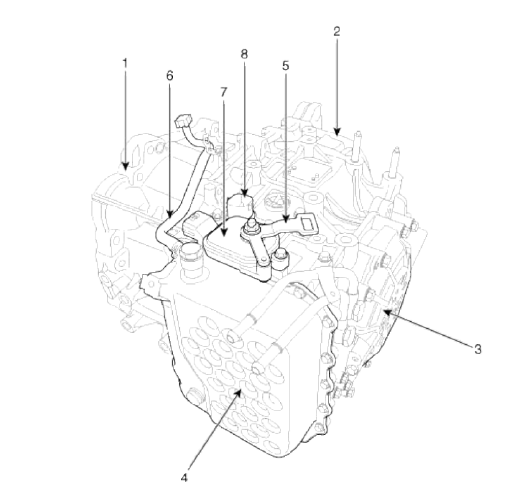

Kia Sportage: Components and Components Location

Components Location

- Converter housing

- Automatic transaxle case

- Rear cover

- Valve body cover

- Manual control lever

- Air breather hose

- Inhibitor switch

- Solenoid valve connector

Repair procedures

Removal

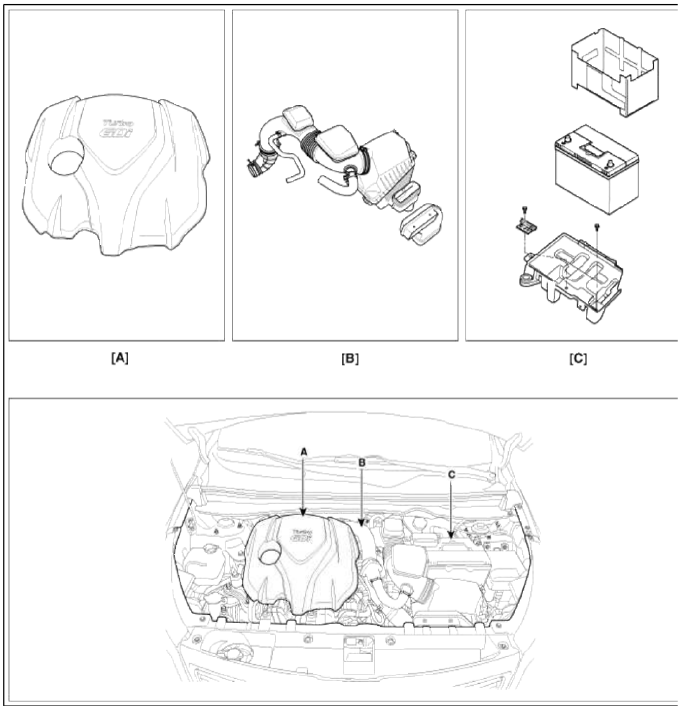

1. Remove the following items;

- Engine cover (A).

- Air cleaner assembly and air duct (B). (Refer to "Intake and Exhaust system" in EM group.)

- Battery and battery tray (C). (Refer to "Charging system" in EE group.)

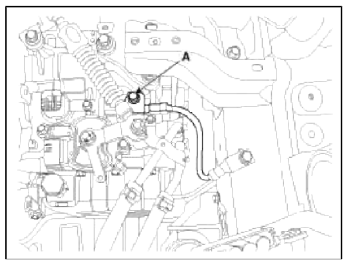

2. Remove the ground line after removing the bolt (A).

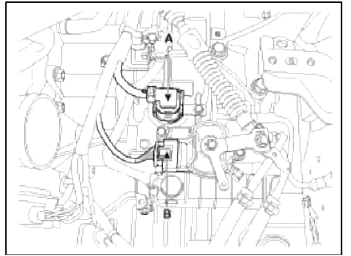

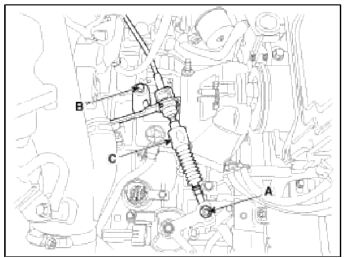

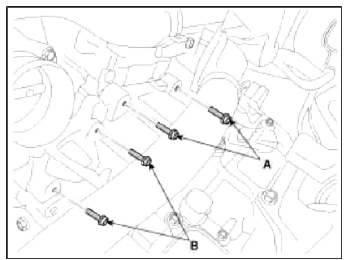

3. Disconnect the solenoid valve connector (A) and inhibitor switch connector (B).

4. Remove the control cable (C) after removing the nut (A) and the bolt (B).

Tightening torque:

(A) 9.8 ~ 14.7 N.m (1.0 ~ 1.5 kgf.m, 7.2 ~ 10.8 lb-ft)

(B) 14.7 ~ 21.6 N.m (1.5 ~ 2.2 kgf.m, 10.9 ~ 15.9 lb-ft)

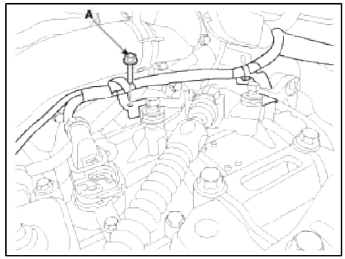

5. Remove the solenoid valve connector and inhibitor switch connector wiring mounting bracket (A).

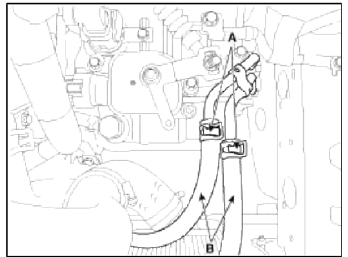

6. Disconnect the hose (B) after removing the automatic transaxle fluid cooler hose clamp (A).

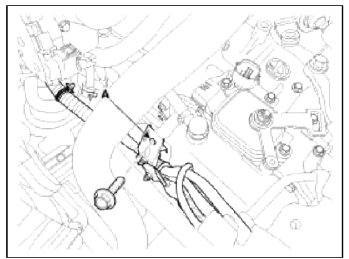

7. Remove the wiring bracket installation bolt (A).

8. Remove the automatic transaxle upper mounting bolt (A-2ea) and the starter motor mounting bolt (B-2ea).

Tightening torque: (A), (B): 42.2 ~ 54.0 N.m (4.3 ~5.5 kgf.m, 31.1 ~ 39.8 lb-ft)

9. Remove the cowl top cover.

(Refer to "Interior (cowl top cover)" in BD group.)

10. Remove the wiper motor.

(Refer to "Windshield Wiper motor" in BE group.)

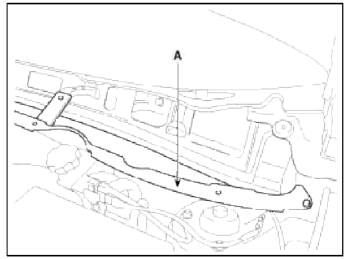

11. Remove the cowl complete assembly panel (A).

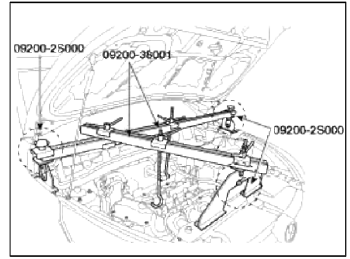

12. Using the engine support fixture (Support SST No.: 09200-2S000, Beam SST No.: 09200-38001), hold the engine and transaxle assembly safely.

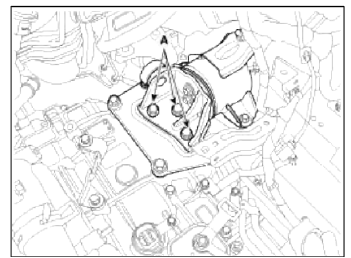

13. Remove the automatic transaxle mounting support bracket bolt (A).

Tightening torque: 88.3 ~ 107.9 N.m (9.0 ~ 11.0 kgf.m, 65.1 ~ 79.8 lb-ft)

14. Lift the vehicle with a jack.

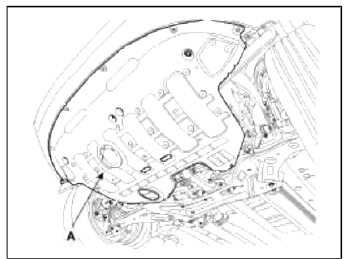

15. Remove the wider cover (A).

Tightening torque: 19.6 ~ 24.5 N.m (2.0 ~ 2.5 kgf.m, 14.5 ~ 18.1 lb-ft)

16. Remove the drive shaft assembly.

(Refer to "Drive shaft assembly" in DS group.)

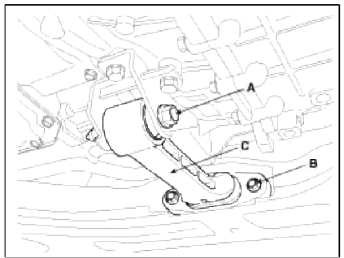

17. Remove the roll rod bracket (C) after removing bolt (A, B).

Tightening torque:

(A) 107.9 ~ 127.5 N.m (11.0 ~ 13.0 kgf.m, 79.6 ~ 94.1 lb-ft)

(B) 49.0 ~ 63.7 N.m (5.0 ~ 6.5 kgf.m, 36.2 ~ 47.0 lb-ft)

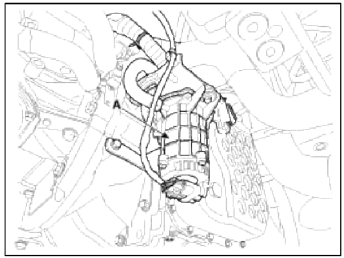

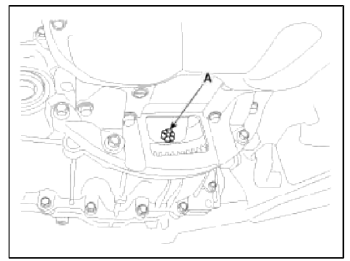

18. Remove the vacuum pump (A).

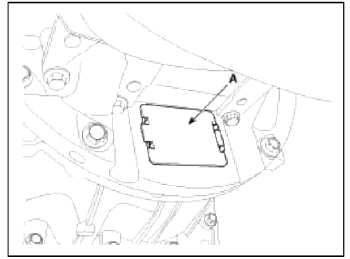

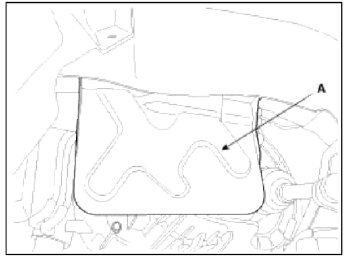

19. Remove the dust cover (A).

20. Remove the torque converter mounting bolt (A-6ea) with rotating the crankshaft.

Tightening torque: 45.1 ~ 52.0 N.m (4.6 ~ 5.3 kgf.m, 33.3 ~ 38.3 lb-ft)

21. Remove the side cover (A).

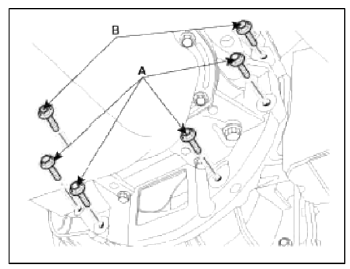

22. Remove the automatic transaxle with a jack after removing the mounting bolt (A-4ea, B-2ea)

Tightening torque:

(A) 42.2 ~ 48.1 N.m (4.3 ~ 4.9 kgf.m, 31.1 ~ 35.4 lb-ft)

(B) 42.2 ~ 54.0 N.m (4.3 ~5.5 kgf.m, 31.1 ~ 39.8 lb-ft)

Installation

1. Installation is the reverse of removal

CAUTION

If the oil seal on the transaxle case side is damaged and fluid is leaking, replace the oil seal with a new unit. When installing the new oil seal, use the specialized tool (oil seal installer, 09453-3L240).

NOTE

After replacement or reinstallation procedure of the automatic transaxle assembly, must perform procedures below.

- Power steering fluid replacement and air bleeding. (Refer to "General information" in ST group)

- Adding automatic transaxle fluid. (Refer to "Hydraulic system (Fluid)" in this group)

- After servicing the automatic transaxle or TCM, clear' the diagnostic

trouble codes (DTC) using the GDS tool.

Diagnostic trouble codes (DTC) cannot be cleared by disconnecting the battery.

- When replacing the automatic transaxle and TCM, reset the diagnostic trouble code by using GDS.

- When deleting diagnostic trouble code, use the GDS as possible.

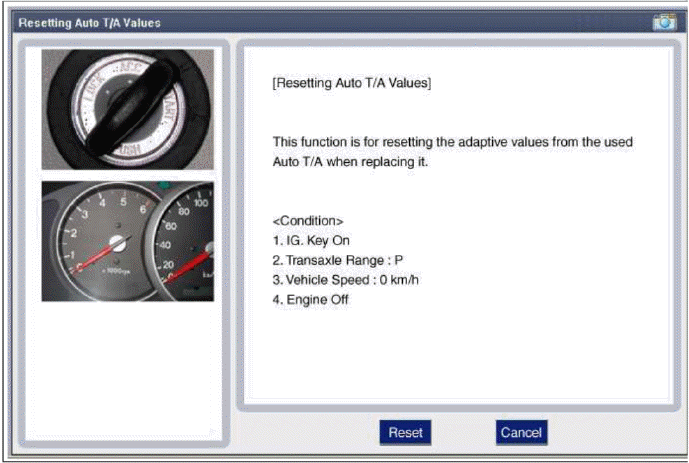

- When replacing the automatic transaxle, reset the automatic transaxle's values by using the GDS.

- Perform TCM learning after replacing the transaxle to prevent slow transaxle response, jerky acceleration and jerky startup. (Refer to "Automatic transaxle control system (Repair procedures)" in this group).

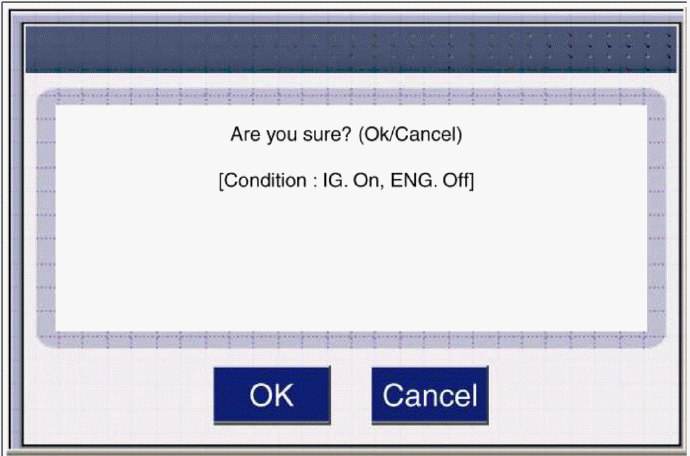

NOTE

- When replacing the automatic transaxle, reset the automatic transaxle's values by using the GDS.[Condition]

- IG Key On

- Transaxle Range: P

- Vehicle Speed: 0 km/h

- Engine Off

READ NEXT:

Description and Operation, Components and Components Location | Oil Pump | Fluid

Description and Operation, Components and Components Location | Oil Pump | Fluid

Description and Operation

Description

The hydraulic system consists of oil, an oil filter, an oil pump, and a valve body (valves and solenoid valves). The oil pump is powered by the engine. A

SEE MORE:

Odometer

Odometer

Type A / Type B

The odometer Indicates the total distance

that the vehicle has been driven

and should be used to determine when

periodic maintenance should be performed.

Odometer range: 0 ~ 1,599,999 km or

999,999 miles.

Distance to empty

Type A / Type B

The distance to empty

Repair procedures

Repair procedures

Refrigerant System Service Basics

Refrigerant Recovery

Use only service equipment that is U.L-listed and is certified to meet the

requirements of SAE J2210 to remove

4FC-134a(R-134a) from the air conditioning system.

CAUTION

Air conditioning refrigerant or lubricant vapor can irritat

Content

- Home

- Kia Sportage - Fifth generation (NQ5) - (2022-2026) - Owner's Manual

- Kia Sportage - Second generation (JEKM) (2005-2015) - Body Workshop Manual

- Kia Sportage Third generation (SL) - (2011-2016) - Service and Repair Manual

- Sitemap

- Top articles