Kia Sportage: Cruise Control Switch

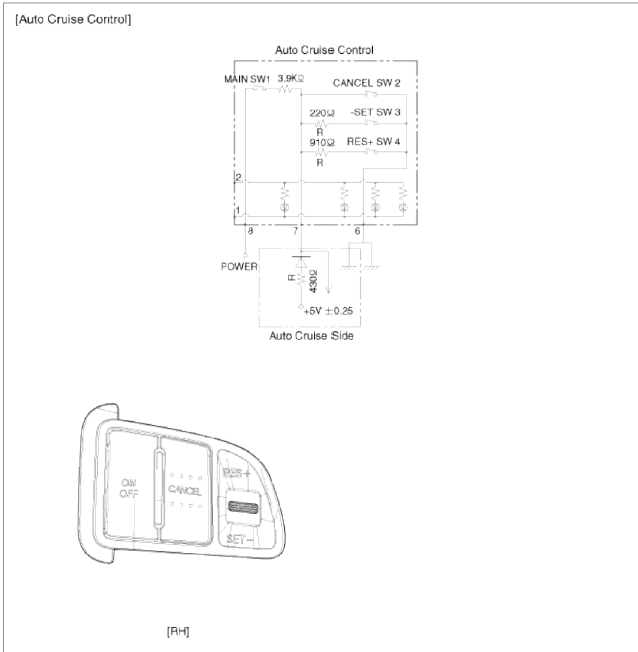

Schematic Diagrams

Circuit Diagram

[Auto Cruise Control]

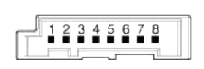

Connector RH

Connector RH

- ILL (-)

- ILL (+)

- -

- -

- -

- ACC GND

- ACC signal

- ACC power

Repair procedures

Removal and Installation

1. Disconnect the battery (-) terminal.

Tightening torque:

Without battery sensor: 7.8 ~ 9.8N.m (0.8 ~ 1.0.kgf.m, 5.8 ~ 7.2lb-ft)

With battery sensor: 4.0 ~ 6.0N.m (0.4 ~ 0.6kgf.m, 3.0 ~ 4.4lb-ft)

2. Remove the airbag module from the steering wheel. (Refer to RT group)

3. Remove the steering wheel. (Refer to ST group)

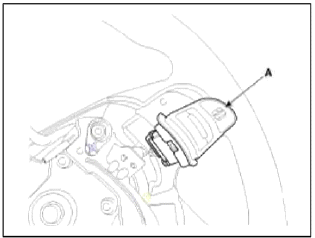

4. Remove the cruise control switch (A) after unfastening the 2 screws and disconnecting the switch connector.

5. Installation is reverse order of removal.

Inspection

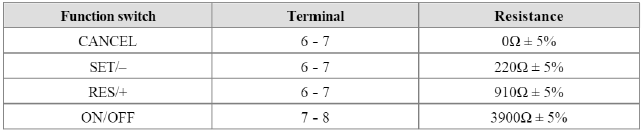

Measuring Resistance

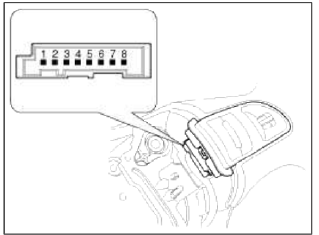

1. Disconnect the cruise control switch connector from the control switch.

2. Measure resistance between terminals on the control switch when each function switch is ON (switch is depressed).

3. If not within specification, replace switch.

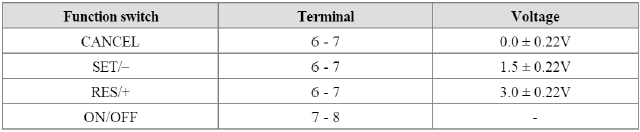

Measuring Voltage

1. Connect the cruise control switch connector to the control switch.

2. Measure voltage between terminals on the harness side connector when each function switch is ON (switch is depressed).

3. If not within specification, inspect the control switch resistance.

The measuring resistance value is not within specification, replace the switch and measure the voltage again.

4. If resistance is OK but, measuring voltage is not within specification, inspect the wiring harness and connectors between the switch and the ECM.

READ NEXT:

General Information

General Information

Specifications

Specifications

Tightening Torques

Repair procedures

Compression Pressure Inspection

NOTE

If the there is lack of power, excessive oil consumption or poor

Engine And Transaxle Assembly

Engine And Transaxle Assembly

Engine Mounting

Components and

Components Location

Components

Transaxle mounting bracket

Roll rod bracket

Sub frame

Engine mounting bracket

Engine mounting support

bracket

SEE MORE:

Repair procedures

Repair procedures

Inspection

Check it by the procedure below to see if the function of the ECM is normal.

1. Turn the ignition key to the "ON" position.

2. Cover the forward facing sensor.

3. Head a light to the rearward looking sensor.

4. The ECM should be darkened as soon as the rearward lo

Resetting the sunroof

Resetting the sunroof

In some circumstances resetting the

sunroof operation may need to be performed.

Some instances where resetting

the sunroof may be required include:

When the 12-volt battery is either disconnected

or discharged

When the sunroof fuse is replaced

If the sunroof one-touch AUTO OPEN/

Content

- Home

- Kia Sportage - Fifth generation (NQ5) - (2022-2026) - Owner's Manual

- Kia Sportage - Second generation (JEKM) (2005-2015) - Body Workshop Manual

- Kia Sportage Third generation (SL) - (2011-2016) - Service and Repair Manual

- Sitemap

- Top articles