Kia Sportage: General Information

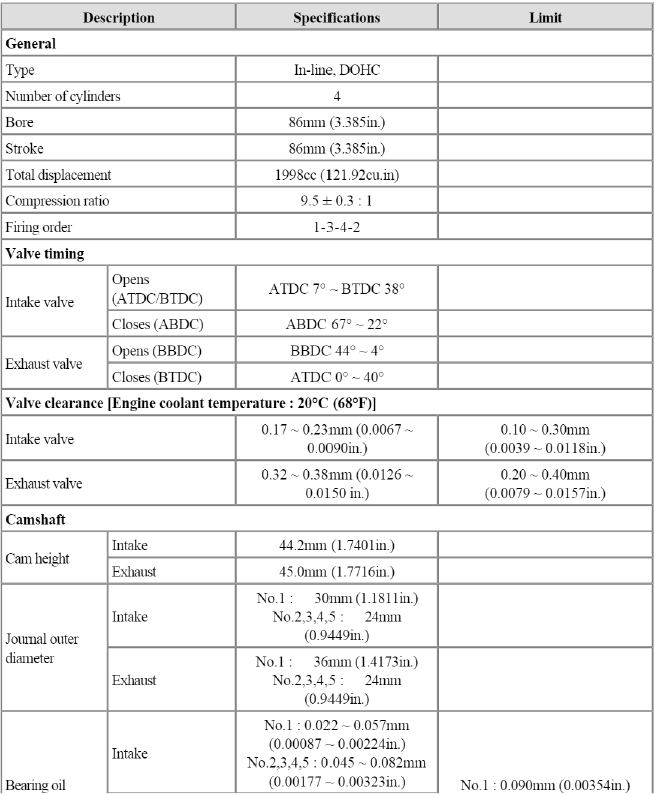

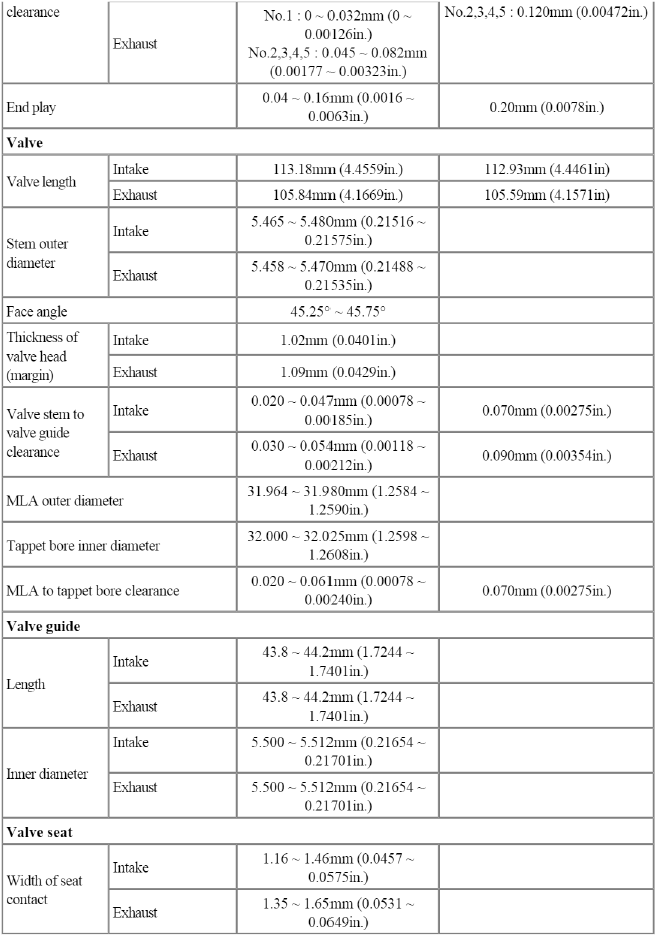

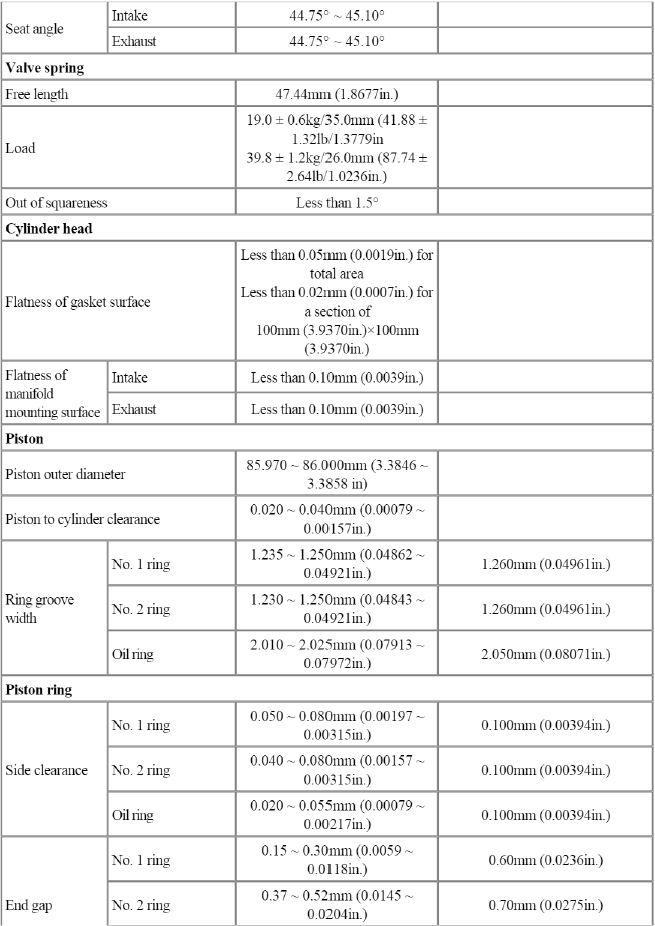

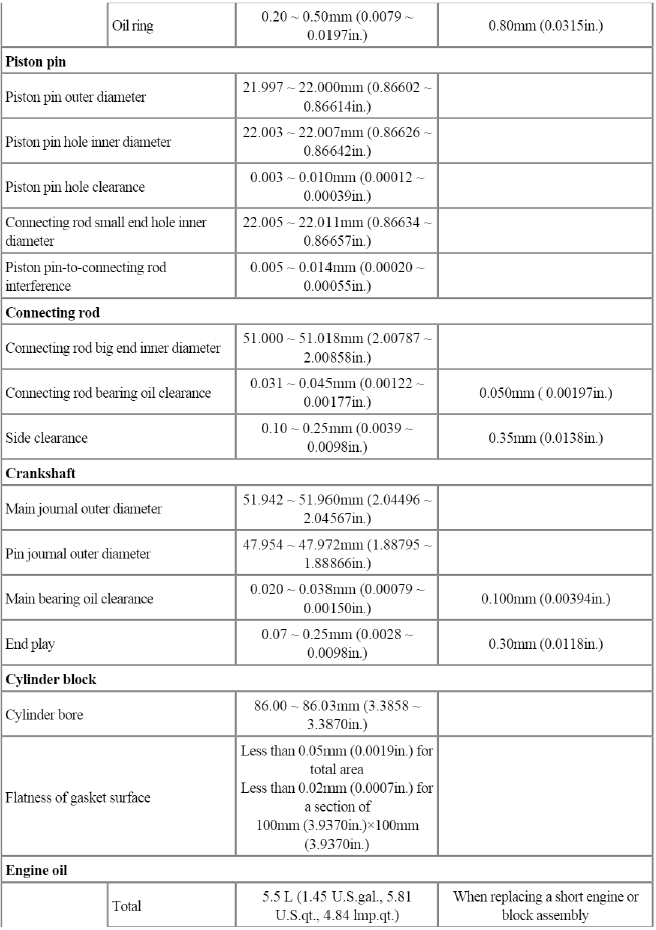

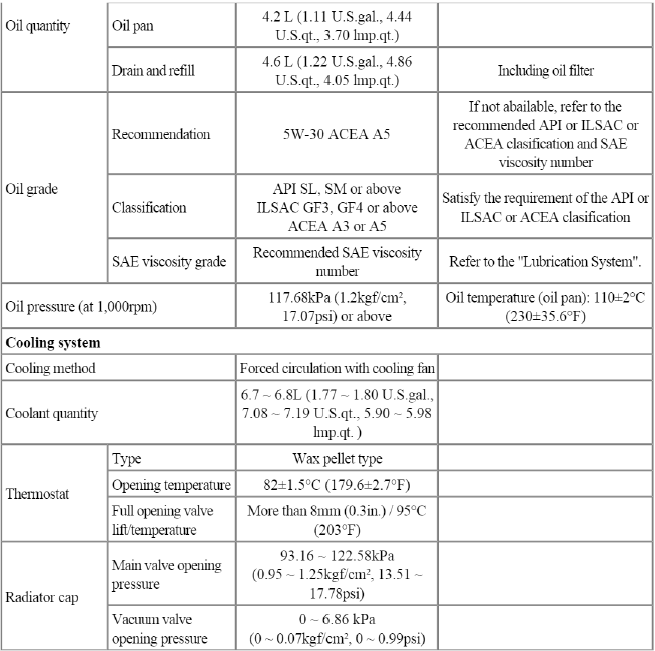

Specifications

Specifications

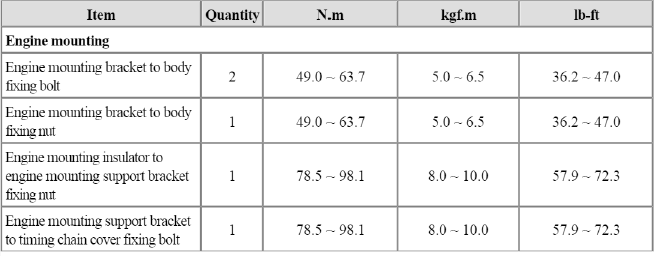

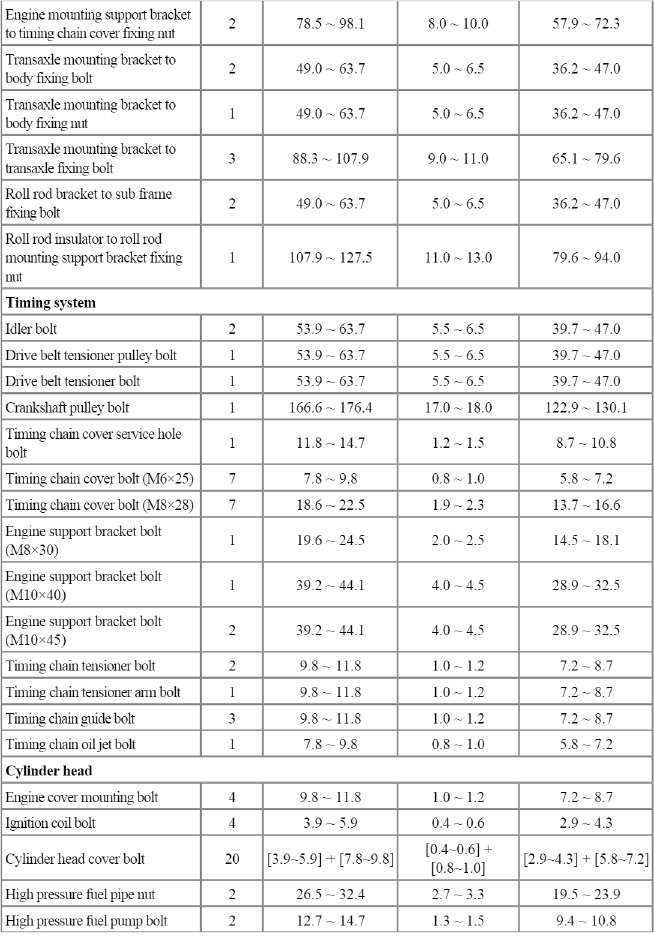

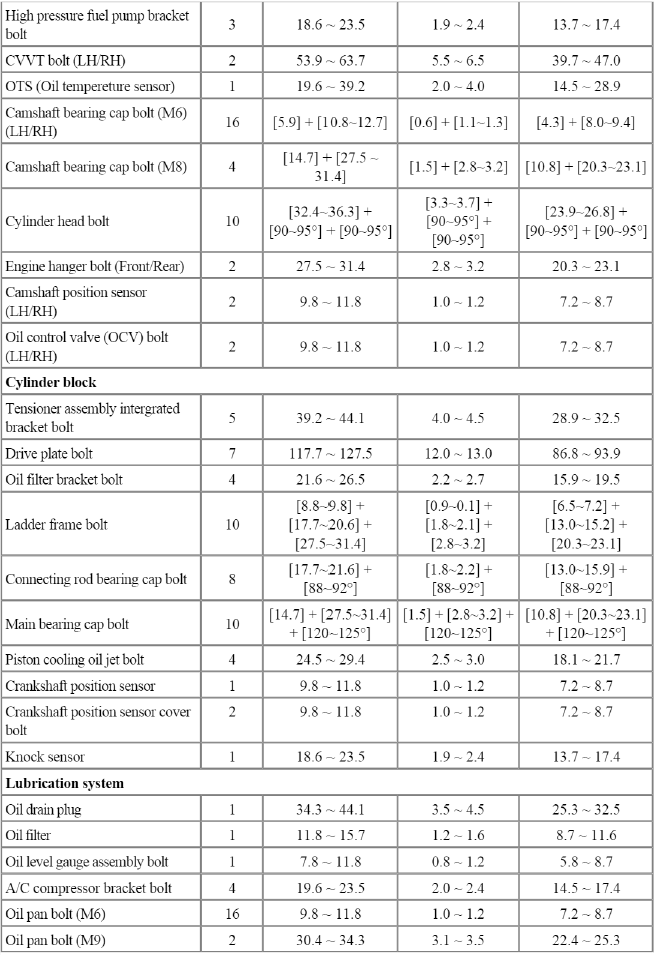

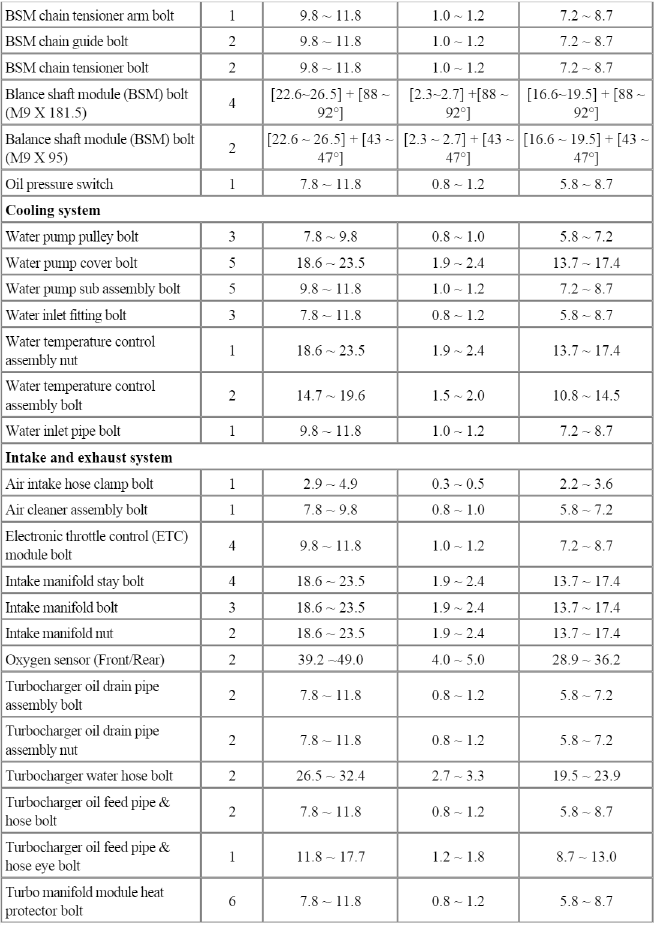

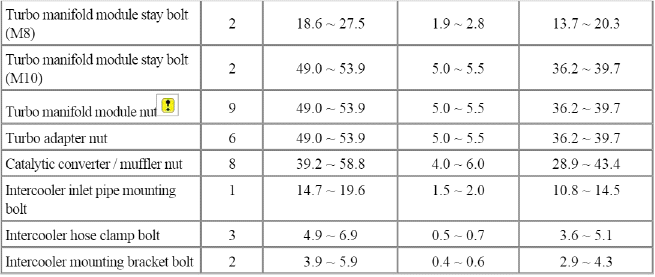

Tightening Torques

Repair procedures

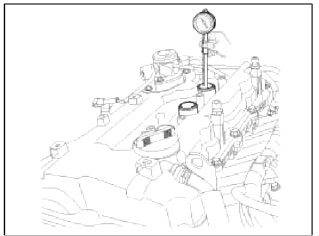

Compression Pressure Inspection

NOTE

If the there is lack of power, excessive oil consumption or poor fuel economy, measure the compression pressure.

1. Warm up and stop engine.

Allow the engine to warm up to normal operating temperature.

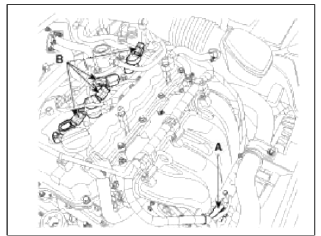

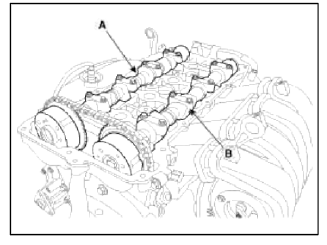

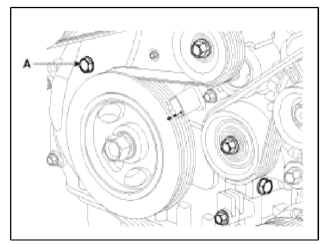

2. Disconnect the injector extension connector (A) and ignition coil connectors (B).

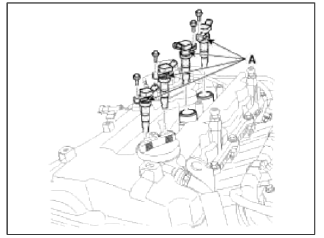

3. Remove ignition coils (A).

4. Remove spark plugs.

Using a 16mm plug wrench, remove the 4 spark plugs.

5. Check cylinder compression pressure.

- Insert a compression gauge into the spark plug hole.

- Fully open the throttle.

- While cranking the engine, measure the compression pressure.

NOTE

Always use a fully charged battery to obtain engine speed of 200 rpm or more.

- Repeat steps (1) through (3) for each cylinder.

NOTE

This measurement must be done in as short a time as possible.

Compression pressure : l,324kPa (13.5kgf/cm2, 192psi) / 200 ~ 250rprn

Minimum pressure: l,177kPa (12.0kgf/cm2,171psi)

Difference between each cylinder : 100кРа (1.0kgf/cm2,15psi) or less

- If the cylinder compression in 1 or more cylinders is low, pour a small amount of engine oil into the cylinder though the spark plug hole and repeat steps (1) through (3) for cylinders with low compression.

- If adding oil helps the compression, it is likely that the piston lings and/or cylinder bore are worn or damaged.

- If pressure stays low, a valve may be sticking or seating is improper, or there may be leakage past the gasket.

6. Reinstall spark plugs.

7. Install ignition coils.

8. Connect the injector extension connector and ignition coil connectors.

9. Some DTC's may exist after the inspection test and may need to be manually cleared with GDS.

Valve Clearance Inspection And Adjustment

NOTE

Inspect and adjust the valve clearance when the engine is cold (Engine coolant temperature : 20ºC (68ºF) ) and cylinder head is installed on the cylinder block.

WARNING

In case of removing the high pressure fuel pump, high pressure fuel pipe, delivery pipe, and injector, there may be injury caused by leakage of the high pressure fuel. So don't do any repair work right after engine stops.

1. Remove the cylinder head cover. (Refer to Timing system in this group)

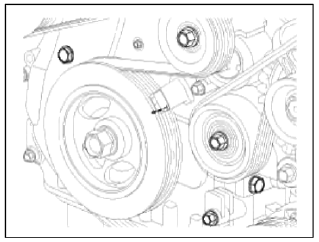

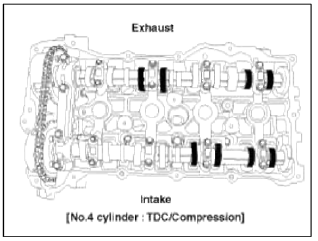

2. Set No. cylinder to TDC/compression.

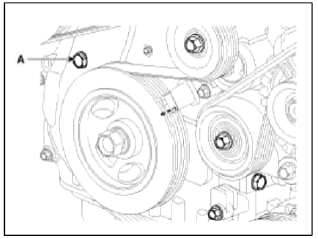

- Turn the crankshaft pulley and align its groove with the timing mark "T" of the lower timing chain cover.

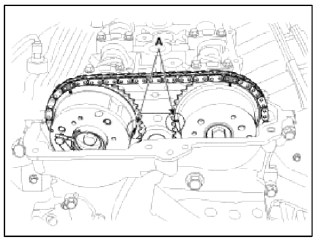

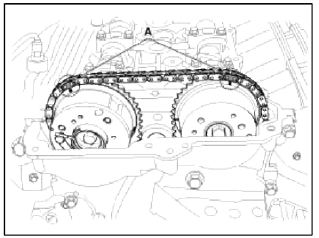

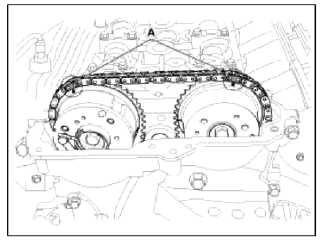

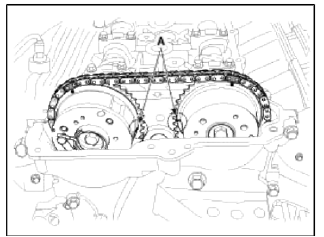

- Check that the TDC marks (A) of the C W T sprockets are in straight line

on the cylinder head surface as

shown in the illustration.

If not, turn the crankshaft one revolution (360º)

3. Inspect the valve clearance.

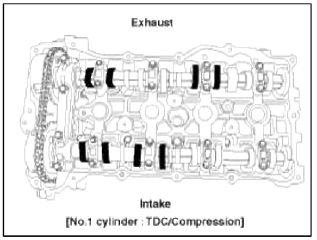

- Check only the valve indicated as shown. Measure the valve clearance.

- Using a thickness gauge, measure the clearance between the tappet and the base circle of camshaft.

- Record the out-of-specification valve clearance measurements. They will be used later to determine the required replacement adjusting tappet.

Valve clearance

Specification

Engine coolant temperature: 20ºC [68ºF]

Limit

Intake : 0.10 ~ 0.30mm (0.0039 ~ 0.0118in.)

Exhaust: 0.20 ~ 0.40mm (0.0079 ~ 0.0157in.)

- Turn the crankshaft pulley one revolution (360º) and align the groove with timing mark "T" of the lower timing chain cover.

- Check only valves indicated as shown. Measure the valve clearance.

4. Adjust the intake and exhaust valve clearance.

- Set the No.1 cylinder to the TDC/compression.

- Mark the timing chains (A) on the timing marks of the CVVT sprockets.

- Remove the front camshaft bearing cap.

- Turn the crankshaft pulley 15º clockwise.

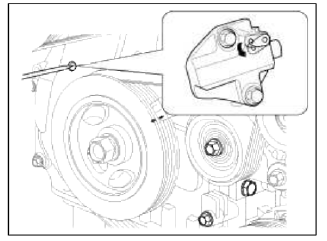

- Remove the service hole bolt (A) of the timing chain cover.

CAUTION

The bolt must not be reused once it has been assembled.

- Remove the intake and exhaust camshaft bearing caps.

- Release the ratchet of the timing chain tensioner by pulling the link down using a thin rod.

- After loosening the timing chain, remove the exhaust CVVT & camshaft assembly (A) and then the intake CVVT & camshaft assembly (B).

CAUTION

When disconnect the timing chain from the CVVT sprocket, hold the timing chain.

- Tie down tuning chain so that it doesn't move.

CAUTION

Be careful not to drop anything inside tuning chain cover.

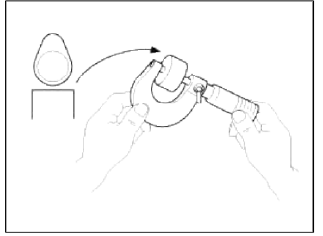

- Measure the thickness of the removed tappet using a micrometer.

- Calculate the thickness of a new tappet so that the valve clearance conies within the specified value.

Valve clearance [Engine coolant temperature : 20ºC (68ºF) ]

T : Thickness of removed tappet

A : Measured valve clearance

N : Thickness of new tappet

Intake : N = T + [A - 0.20mm (0.0079in.) ]

Exhaust: N = T + [A - 0.30mm (0.0118in.) ]

- Select a new tappet with a thickness as close as possible to the calculated value.

NOTE

Shims are available in 47 size increments of 0.015mm (0.0006m.) from 3.00mm. (0.118in.) to 3.690mm (0.1452in.)

- Place a new tappet on the cylinder head.

- Hold the timing chain, and place the intake CVVT & camshaft assembly.

- Place the exhaust CVVT & camshaft assembly after releasing the ratchet of the timing chain tensioner.

NOTE

The timing marks of each CVVT sprocket should be matched with timing marks (painted link) of timing chain when installing the timing chain.

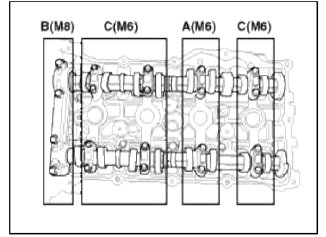

- Install the camshaft bearing caps in then proper locations.

Tightening order

Group A → Group В → Group C

Tightening torque

Step 1

M6 : 5.9N.m (0.6kgf.m, 4.3lb-ft)

M8 : 14.7N.m (1.5kgf.m, 10.8lb-ft)

Step 2

M6 : 10.8 ~ 12.7N.m (1.1 ~ 1.3kgf.m, 8.0 ~ 9.4lb-ft)

M8 : 27.5 ~ 31.4N.m (2.8 ~ 3.2kgf.m, 20.3 ~ 23.1lb-ft)

- Install the service hole bolt (A).

Tightening torque: 11.8 ~ 14.7N.m (1.2 ~ 1.5kgf.m, 8.7 ~ 10.8lb-ft)

- Turn the crankshaft two turns in the operating direction (clockwise), and then check that the TDC marks (A) of the CVVT sprockets are in straight line on the cylinder head surface.

- Recheck the valve clearance.

Valve clearance [Engine coolant temperature : 20ºC (68ºF) ]

[Specification]

Intake : 0.17 ~ 0.23mm (0.0067 ~ 0.0090 in.)

Exhaust: 0.32 ~ 0.38mm (0.0126 ~ 0.0150 in.)

- Install the cylinder head cover. (Refer to Timing system in this group

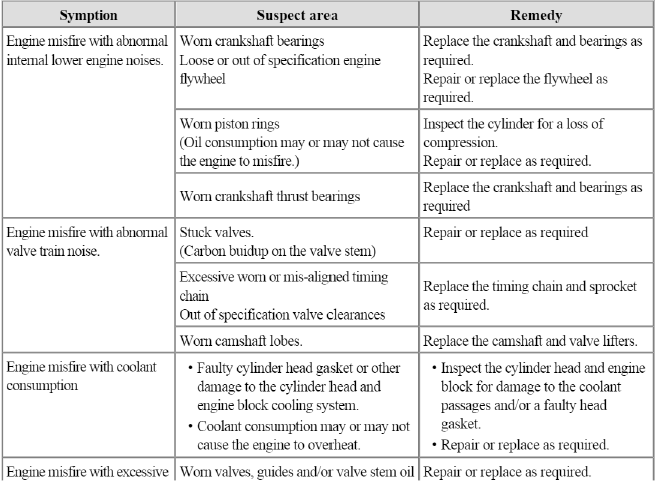

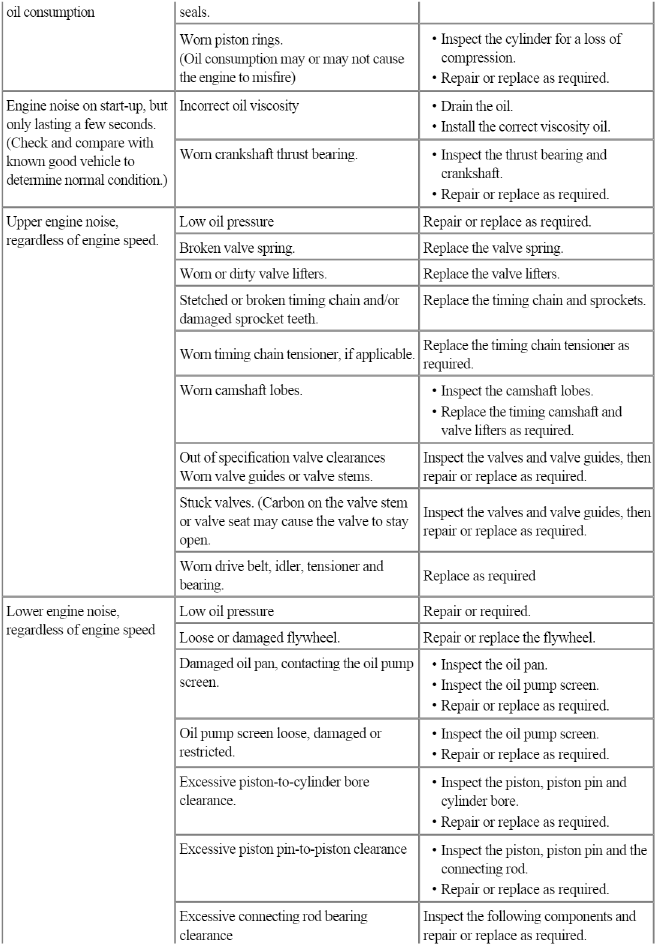

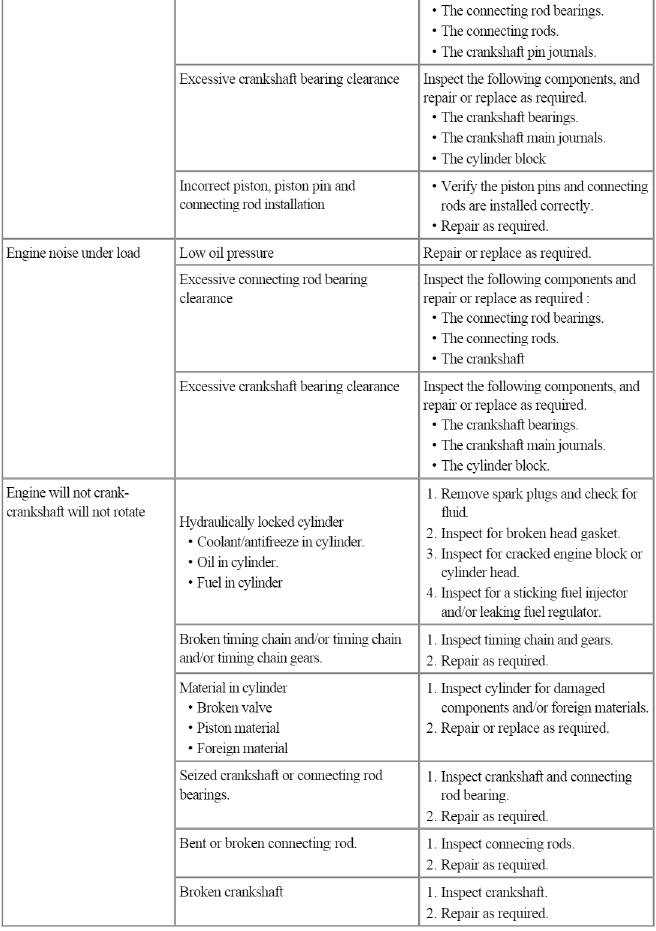

Troubleshooting

Troubleshooting

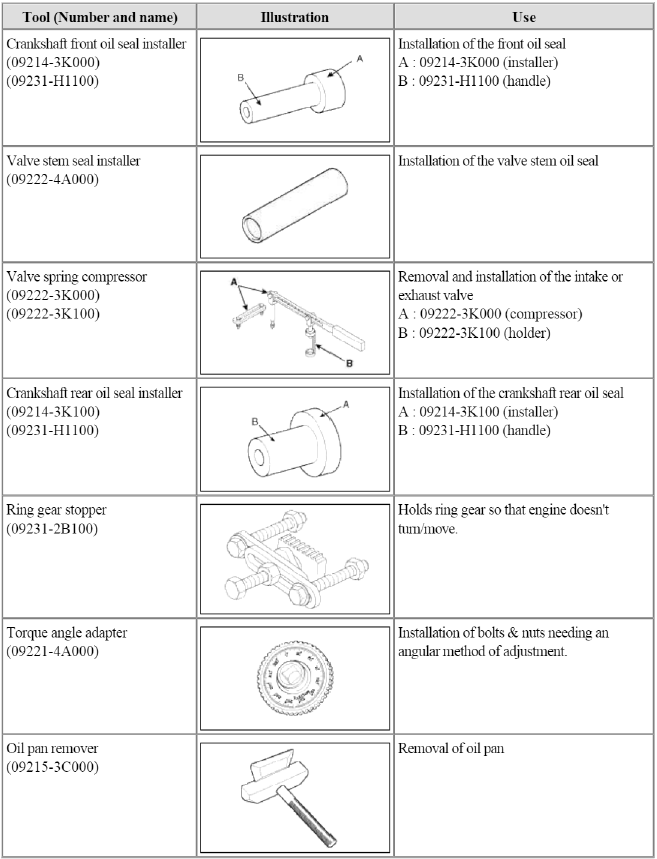

Special Service Tools

Special Service Tools

READ NEXT:

Engine And Transaxle Assembly

Engine And Transaxle Assembly

Engine Mounting

Components and

Components Location

Components

Transaxle mounting bracket

Roll rod bracket

Sub frame

Engine mounting bracket

Engine mounting support

bracket

Components and Components Location | Removal - Repair procedures

Components and Components Location | Removal - Repair procedures

Components

Intake camshaft

Exhaust camshaft

Intake CVVT assembly

Exhaust CVVT assembly

Timing chain

Timing chain guide

Timing chain tensioner arm

Timi

SEE MORE:

Selecting a CRS

Selecting a CRS

When selecting a CRS for your child,

always:

Make sure the CRS has a label certifying

that it meets applicable Federal

Motor Vehicle Safety Standards

(FMVSS 213).

Select a child restraint based on your

child's height and weight. The

required label or the instructions for

use t

Components and ComponentsLocation | Repair procedures

Components and ComponentsLocation | Repair procedures

Components

Front driveshaft (LH)

Inner shaft

Front driveshaft (RH)

[LH]

Split pin

Castle nut

Washer

BJ assembly

Clip A

Ð’J boot band

Ð’J boot

Dynamic damper band

Dynamic damper

Shaft

VTJ boot band

Content

- Home

- Kia Sportage - Fifth generation (NQ5) - (2022-2026) - Owner's Manual

- Kia Sportage - Second generation (JEKM) (2005-2015) - Body Workshop Manual

- Kia Sportage Third generation (SL) - (2011-2016) - Service and Repair Manual

- Sitemap

- Top articles