Kia Sportage: Direct Electro Hydraulic Actuator Coupling

Description and Operation

Description

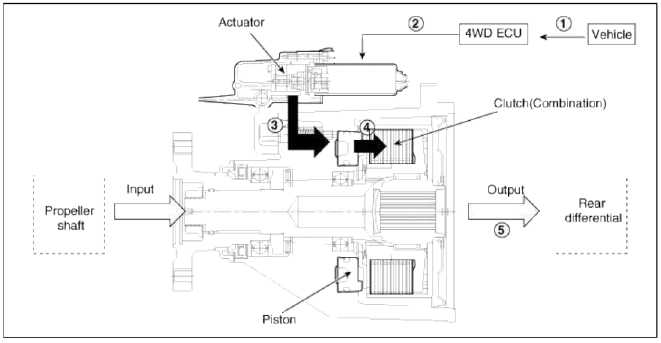

4WD ECU processes signals from various sensors and determines the current road and driving conditions. The ECU then utilizes this information to implement precision control over the 4WD coupling's multi-plate clutch and variably adjust the amount of torque delivered to the rear wheels.

Four Wheel Drive (4WD) transfer mode selection

1. AUTO MODE:

- When driving in 4WD AUTO mode, the vehicle operates similar to conventional 2WD vehicles under normal operating conditions. However, if the system determines that there is a need for the 4WD mode, the engine's driving power is distributed to all four wheels automatically without driver intervention.

- When driving on normal roads and pavement, the vehicle moves similar to conventional 2WD vehicles

2. LOCK MODE:

- This mode is used for climbing or descending sharp grades, off-road driving, driving on sandy and muddy roads, etc., to maximize traction.

- This mode automatically begins to deactivate at speeds above 30 km/h (19 mph) and is shifted to 4WD AUTO mode at speed above 40 km h (25 mph). If the vehicle speed decelerates to below 30 km/h (19 mph), however, the transfer mode is shifted into 4WD LOCK mode again.

Electronic Coupling - 4WD Control (By Driving Condition)

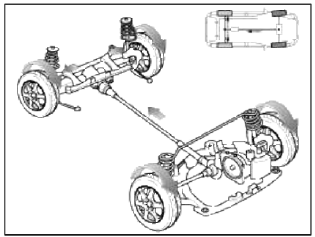

1. Cruising (Auto Mode)

- Power is delivered mostly to the front wheels.

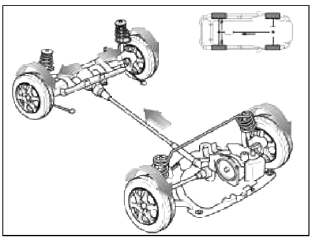

2. Cornering (Auto Mode)

- Adjusts the amount of power to the rear wheels based on the turning radius and cornering speed.

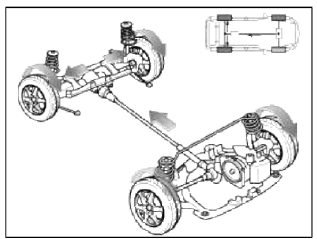

3. Wheel Slip (Auto Mode)

- If one or both of the front wheels lose fraction, the system transfers an appropriate amount of power to the rear wheels based on the slip amount at the front wheels.

4. Lock Mode

- Maximizes rough terrain performance (active only at speeds below 40 km/h).

Operation

Electronic Coupling

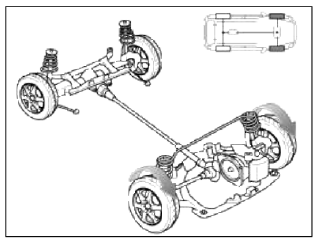

[Inactive]

![[Active]](images/books/1921/1/index%2027.png)

[Active]

Operation Order

1. 4WD ECU receives CAN signals from the vehicle's sensors.

2. 4WD ECU calculates the necessary amount of rear-wheel torque and sends the corresponding driving current to the actuator (electronic motor and hydraulic pump).

3. Hydraulic pressure generated by the actuator moves the piston.

4. Friction from the piston's movement engages the clutch.

5. Power is delivered to the rear wheels.

Components and Components Location

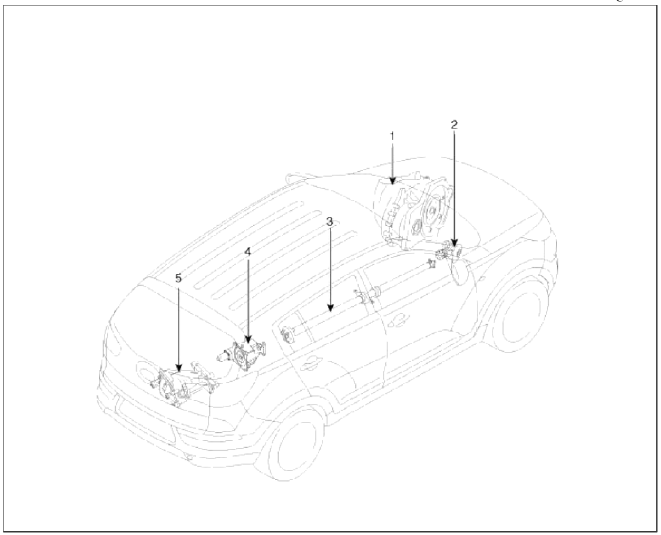

Component Location

- Automatic transaxle

- Transfer assembly

- Propeller shaft

- Coupling assembly

- Differential assembly

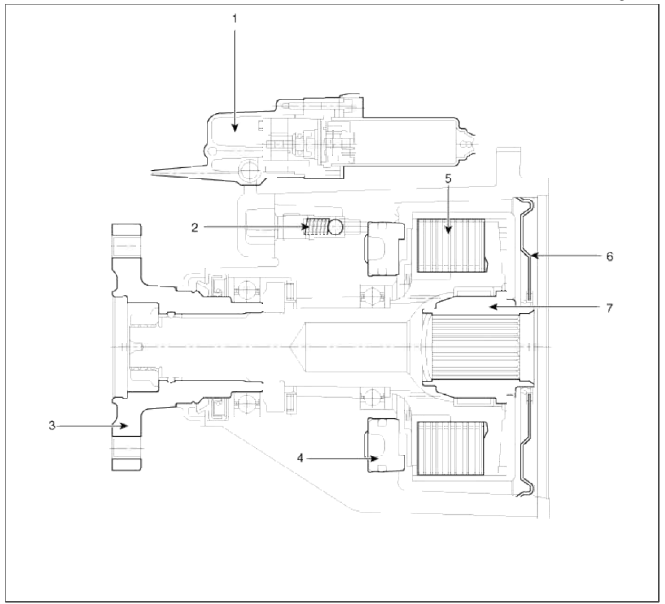

Components

- Actuator

- Bleed valve

- Flange & Input shaft

- Piston

- Clutch pack

- Oil seal cover

- Hub

Repair procedures

Inspection

NOTE

All units are filled up with coupling fluid (ultra-low viscosity ATF) prior to shipping. Inspection, fill-up, and replacement of coupling fluid is therefore not necessary (zero maintenance, lifetime fluid).

Removal

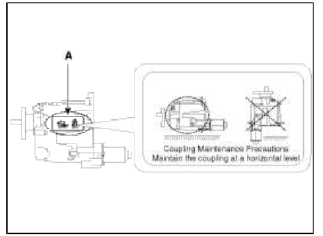

CAUTION

Coupling Maintenance Precautions

Maintain the coupling at a horizontal level.

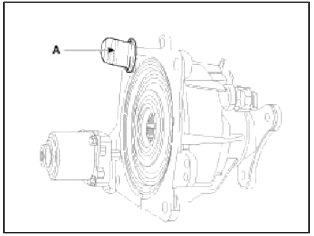

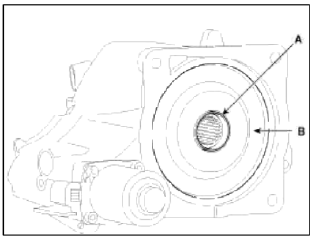

- Refer to the handling caution level (A) when servicing the coupling (removal, installation, replacement, etc.).

- Remove the dipstick and then mount the coupling assembly to the rear differential assembly.

- Maintain the coupling at a horizontal level after removing the dipstick to prevent the fluid from spilling out.

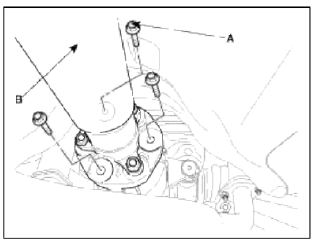

1. Remove the 4WD coupling assembly bolts (A-3ea) mounted to the rear propeller shaft (B).

Tightening torque: 49.0~68.6N.m (5.0~7.0kgf.m, 36.2~50.6lb-ft)

2. Using a flat tool, separate the propeller shaft from 4WD coupling assembly.

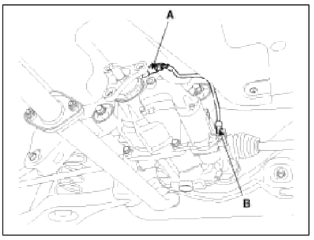

3. Remove the electric magnetic clutch connector (A).

4. Remove the 4WD coupling assembly mounting bolts (A-4ea).

Tightening torque: 58.8~63.7N.m (6.0~6.5kgf.m, 43.4~47.0lb-ft)

5. Using a flat tool, separate the 4WD coupling assembly from the rear differential carrier assembly.

Installation

1. Installation is the reverse of removal.

NOTE

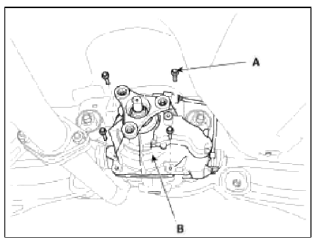

- Grease the spline hole (A) of the coupling assembly.

Grease

Extreme Pressure (EP) grease containing molybdenum disulfide (MoS2)

- When installation the coupling, be careful not to damage the oil seal (B).

CAUTION

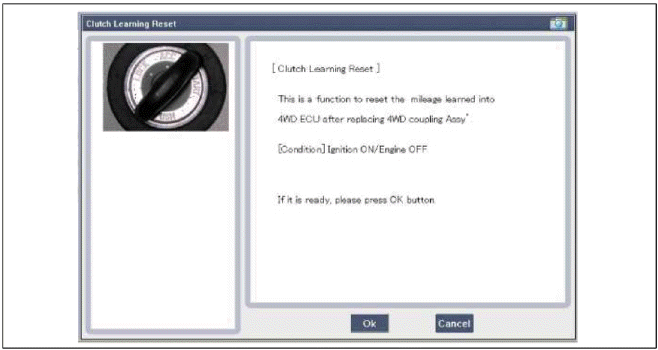

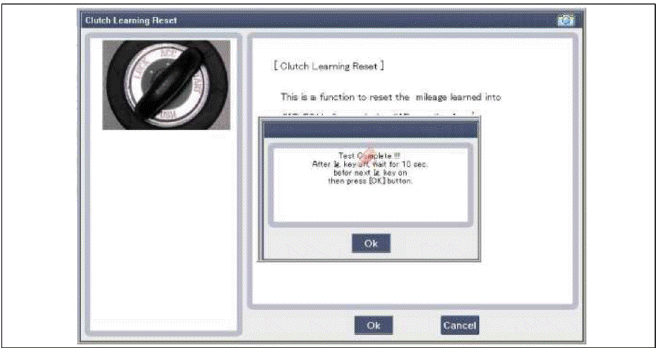

After replacing the coupling, reset the 4WD ECU's clutch learing using the GDS tool. (Refer to "Coupling assembly" in 4WD group).

Adjustment

Description

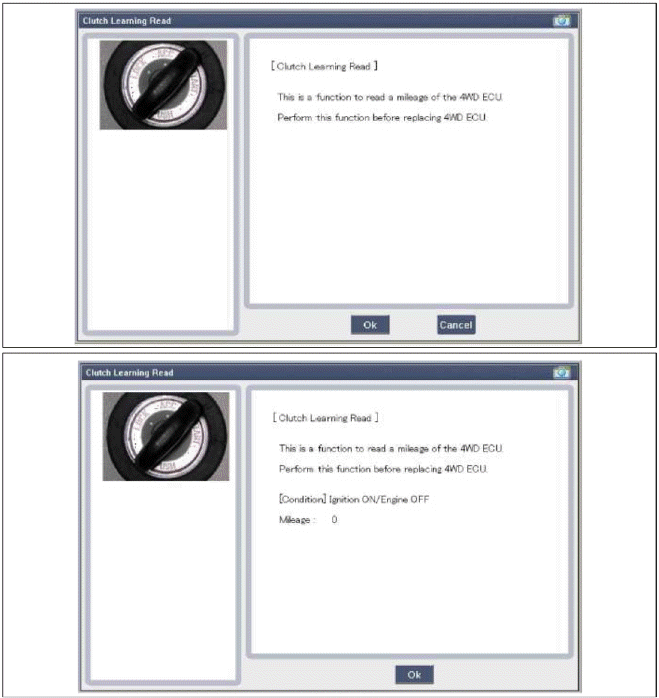

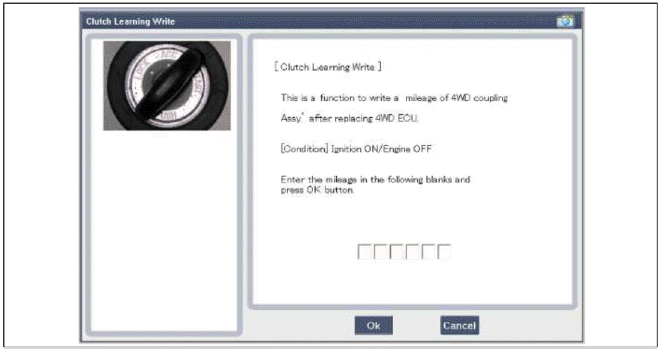

The friction material inside the coupling will degrade over time. Therefore, corresponding compensation values must be referenced and entered after replacing the controller or the coupling.

Compensation Requirement and Procedure

1. Simultaneous replacement of 4WD ECU (Controller) and coupling

- Does not require compensation.

2. Replacement of coupling only

- Reset the 4WD ECU's (Controller) clutch learing.

3. Replacement of 4WD ECU (Controller) only

- Before replacement: Check the ECU's clutch tearing.

- After replacement: Enter the original ECU's clutch tearing into the replacement ECU.

READ NEXT:

Oil hydraulic Motor (Actuator)

Oil hydraulic Motor (Actuator)

Description and Operation

Description

The 4WD ECM controls the Pump Motor Pump (Actuator) to generating an oil

pressure. The pressure engages a multiple

disk clutch to transfer torque to th

Pressure Sensor

Pressure Sensor

Description and Operation

Description

The 4WD ECU makes a Motor Pump (Actuator) turn round for generating an oil

pressure. And then it presses a multiple

disk clutch and transfers the gener

SEE MORE:

Folding the rear seat

Folding the rear seat

The rear seatbacks may be folded to

facilitate carrying long items or to

increase the luggage capacity of the

vehicle.

WARNING

Folded Seatback

The purpose of the fold-down rear seatbacks

is to allow you to carry longer

objects that could not otherwise be

accommodated.

Never allow a pass

Driving your vehicle

Driving your vehicle

Be sure the exhaust system does not leak

The exhaust system should be checked

whenever the vehicle is raised to change

the oil or for any other purpose.

If you hear a change in the sound of the

exhaust or if you drive over something

that strikes the underneath side of the

vehicle, have the

Content

- Home

- Kia Sportage - Fifth generation (NQ5) - (2022-2026) - Owner's Manual

- Kia Sportage - Second generation (JEKM) (2005-2015) - Body Workshop Manual

- Kia Sportage Third generation (SL) - (2011-2016) - Service and Repair Manual

- Sitemap

- Top articles