Kia Sportage: Inhibitor Switch

Description and Operation

Description

Inhibitor Switch monitors the lever's position (PRXD) and is used to control gear setting signals.

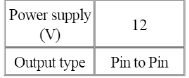

Specifications

Specifications

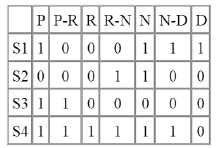

Type: Combination of output signals from 4 terminals

Signal Code Table

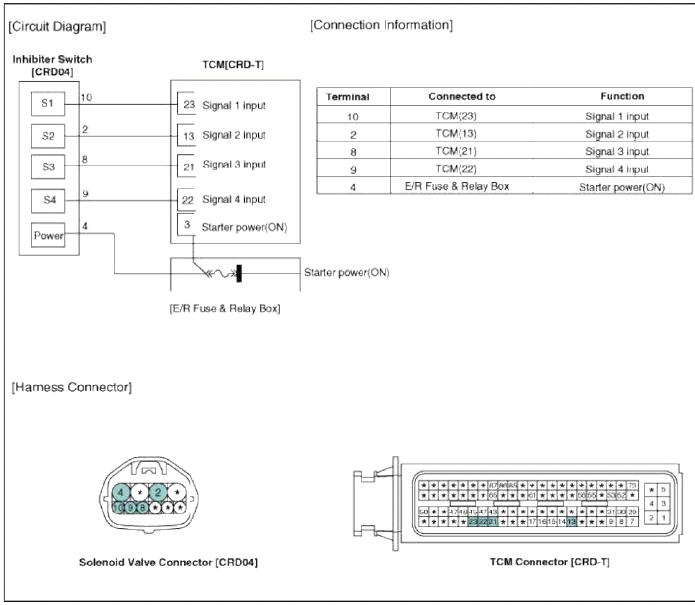

Schematic Diagrams

Circuit Diagram

Repair procedures

Removal

1. Make sure vehicle does not roll before setting room side shift lever and T/M side manual control lever to "N" position.

2. Remove the battery and the battery tray. (Refer to "Charging system" in EE group.)

3. Remove the air cleaner assembly. (Refer to "Intake manifold" in EM group.)

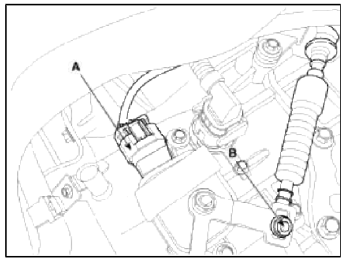

4. Remove the shift cable mounting nut (B).

Tightening torque: 7.8 ~ 11.8 N.m (0.8 ~ 1.2 kgf.m, 5.7 ~ 8.6 lb-ft)

5. Disconnect the inhibitor switch connector (A).

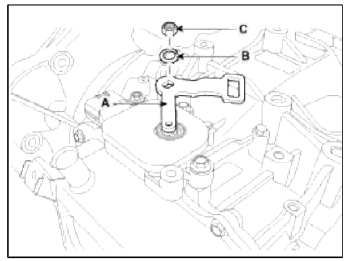

6. Remove the manual control lever (A) and the washer (B) after removing a nut (C).

CAUTION

When installing, affix the manual control lever and the inhibitor switch with Ø5mm (0.1969in.). Then tighten the inhibitor assembly mounting bolts.

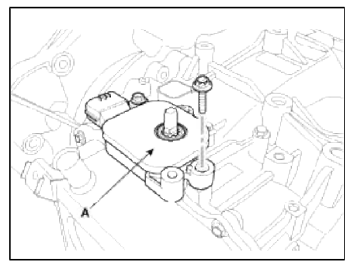

7. Remove the inhibitor assembly (A) after removing the bolts (2ea).

Tightening torque: 9.8 ~ 11.8 N.m (1.0 ~ 1.2 kgf.m, 7.2 ~ 8.7 lb-ft)

CAUTION

When installing, tighten the inhibitor assembly mounting bolt lightly, so that necessary adjustments can be made. Tighten to specifications.

Installation

1. Installation is the reverse of removal.

READ NEXT:

Shift Lever

Shift Lever

Components and Components Location

Components

Shift lever knob & boots

assembly

Shift lever assembly

Control cable assembly

Manual control lever (T/M side)

Repair procedure

General Information

General Information

Specifications

Specifications

Tightening Torque

Special Service Tools

Special Tools

Troubleshooting

Troubleshooting

SEE MORE:

Armed stage

Armed stage

Theft-alarm system

This system is designed to provide protection

from unauthorized entry into the

vehicle.

This system is operated in three stages:

Armed stage

Theft-alarm stage

Disarmed stage

If triggered, the system provides an

audible alarm with blinking of the hazard

warni

Luggage net holder

Luggage net holder

To keep items from shifting in the cargo

area, you can use the 4 holders located

in the cargo area to attach the luggage

net (if equipped), or you can fold the

luggage net into half and attach it

upwards by using the additional 2 holders

located on each side.

If necessary, contact an auth

Content

- Home

- Kia Sportage - Fifth generation (NQ5) - (2022-2026) - Owner's Manual

- Kia Sportage - Second generation (JEKM) (2005-2015) - Body Workshop Manual

- Kia Sportage Third generation (SL) - (2011-2016) - Service and Repair Manual

- Sitemap

- Top articles