Kia Sportage: Input Speed Sensor

Description and Operation

Description

Input speed sensor is a vital unit that measures the rate of rotation of the input shaft inside the transaxle and delivers the readings to the TCM. The sensor provides critical input data that's used in feedback control, damper clutch control, gear setting control, line pressure control, clutch activation pressure control, and sensor fault analysis.

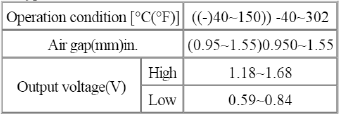

Specifications

Specifications

Type: Hall effect sensor

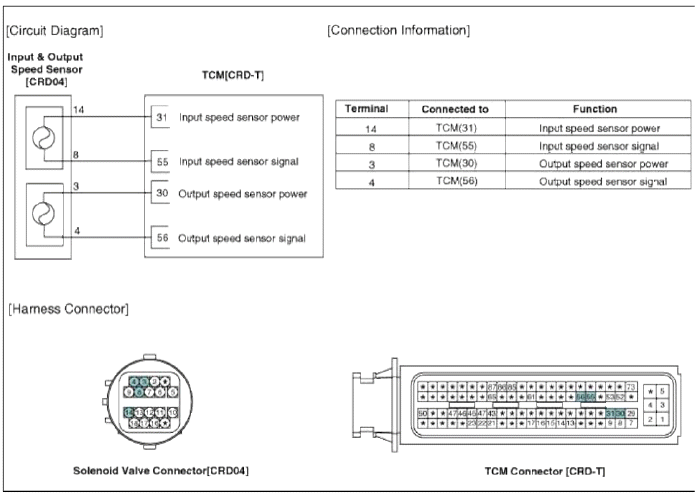

Schematic Diagrams

Circuit Diagram

Troubleshooting

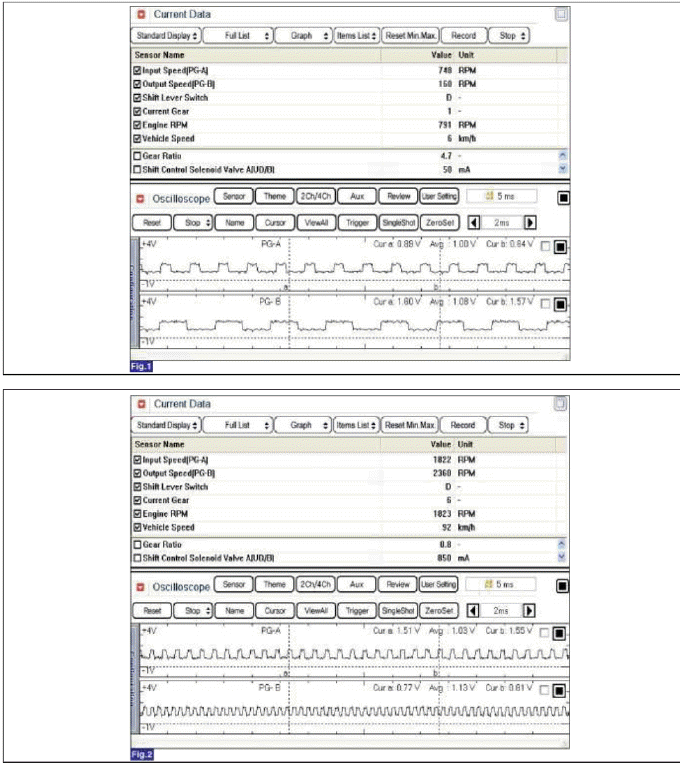

Signal Waveform

Fig 1) Input/Output speed sensor at low speed

Fig 2) Input/Output speed sensor at high speed

Repair procedures

Inspection

1. Check signal waveform of Input & output speed sensor using the GDS.

Specification: Refer to "Signal Wave Form" section.

Removal

1. Remove the battery and the battery tray. (Refer to "Charging system" in EE group.)

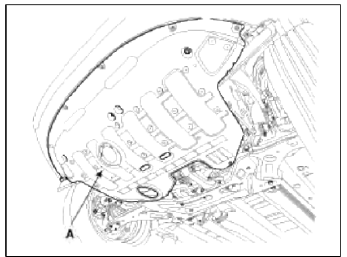

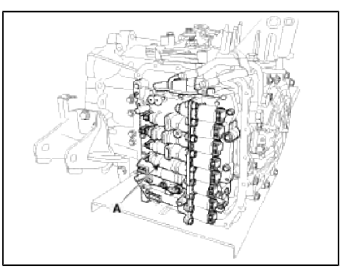

2. Remove the under cover (A).

Tightening torque: 19.6 ~ 24.5 N.m (2.0 ~ 2.5 kgf.m, 14.5 ~ 18.1 lb-ft)

3. Replace new gasket and the plug after draining the automatic transaxle fluid by removing the drain plug. (Refer to "Hydraulic system (Fluid)" in this group)

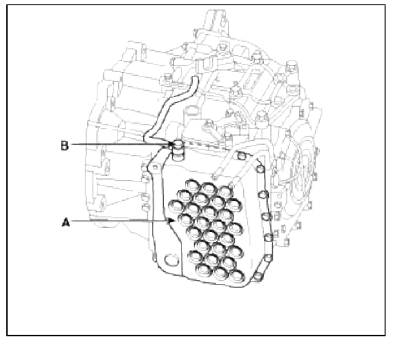

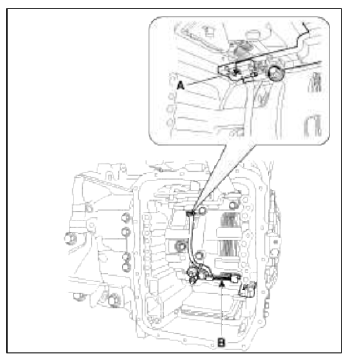

4. Remove the valve body cover (A) and eyebolt (B).

Tightening torque:

(A) 13.8 ~ 14.7 N.m (1.3 ~ 1.5 kgf.m, 9.4 ~ 10.8 lb-ft)

(B) 34.3 ~ 44.1 N.m (3.5 ~ 4.5 kgf.m, 25.3 ~ 32.6 lb-ft)

CAUTION

Always replace the gasket of the eyebolt use new one whenever loosening eyebolt.

NOTE

Remove installation bolts in the engine compartment first and then remove others under the vehicle.

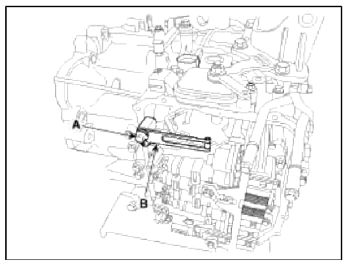

5. Remove the plate and the detent spring (A) after removing the bolt

Tightening torque: 24.5 ~ 35.3 N.m (2.5 ~ 3.6 kgf.m, 18.1 ~ 26.0 lb-ft)

6. Remove the bolt (3ea) after disconnecting the solenoid valve connector (B) and the oil temperature sensor connector (A).

Tightening torque: 9.8 ~ 11.8 N.m (1.0 ~ 1.2 kgf.m, 7.2 ~ 8.7 lb-ft)

CAUTION

Be careful not to damage the harness lock connector.

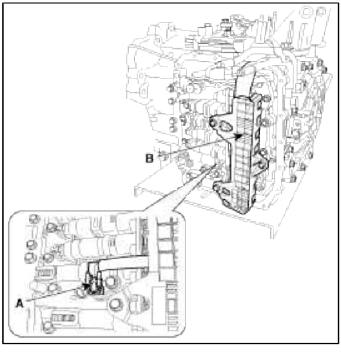

7. Remove the valve body assembly (A).

Tightening torque: 9.8 ~ 11.8 N.m (1.0 ~ 1.2 kgf.m, 7.2 ~ 8.7 lb-ft)

8. Disconnect the input & output speed sensor connector (A).

9. Remove the input & output speed sensor (B) after removing the bolts(2ea).

Tightening torque: 9.8 ~ 11.8 N.m (1.0 ~ 1.2 kgf.m, 7.2 ~ 8.7 lb-ft)

Installation

1. Installation is the reverse of removal.

NOTE

After replacement or reinstallation procedure of the valve body assembly, must perform procedures below.

- Continue to apply liquid gasket at application points at the valve body cover with Ø2.5mm (0.0984in.) thickness.

Liquid gasket Part name : Threebond 1281B or LOCTITE FMD-546

- Adding automatic transaxle fluid. (Refer to "Hydraulic system (Fluid)" in this group)

READ NEXT:

Output Speed Sensor

Output Speed Sensor

Description and Operation

Description

The output speed sensor is a vital unit that measures the rate of rotation of

the transaxle's turbine shaft and output

shaft, and delivers the read

Torque Converter Control Solenoid Valve (T/CON_VFS) | 26 Brake Control Solenoid Valve (26/B_VFS)

Torque Converter Control Solenoid Valve (T/CON_VFS) | 26 Brake Control Solenoid Valve (26/B_VFS)

Description and Operation

Description

Torque converter control solenoid valve (T/CON_VFS) is attached to the valve body. This variable force solenoid valve directly controls the hydraulic pre

SEE MORE:

Corrosion protection

Corrosion protection

Protecting your vehicle from corrosion

By using the most advanced design and

construction practices to combat corrosion,

we produce vehicles of the highest

quality. However, this is only part of the

job. To achieve the long-term corrosion

resistance your vehicle can deliver, the

owner's c

Preparation for assembly - Replacing body panel

Preparation for assembly - Replacing body panel

Preparation for assembly

1. Spot weld finish

Use a disk grinder or similar tool to finish spot weld

mark. Do not grind more than is necessary to smooth

surface.

2. Panel preparation

Repair any bent or uneven areas with a hammer to

improve the assembly process.

3. Cutting a rough area for

Content

- Home

- Kia Sportage - Fifth generation (NQ5) - (2022-2026) - Owner's Manual

- Kia Sportage - Second generation (JEKM) (2005-2015) - Body Workshop Manual

- Kia Sportage Third generation (SL) - (2011-2016) - Service and Repair Manual

- Sitemap

- Top articles