Kia Sportage: Intake Manifold

Components and Components Location

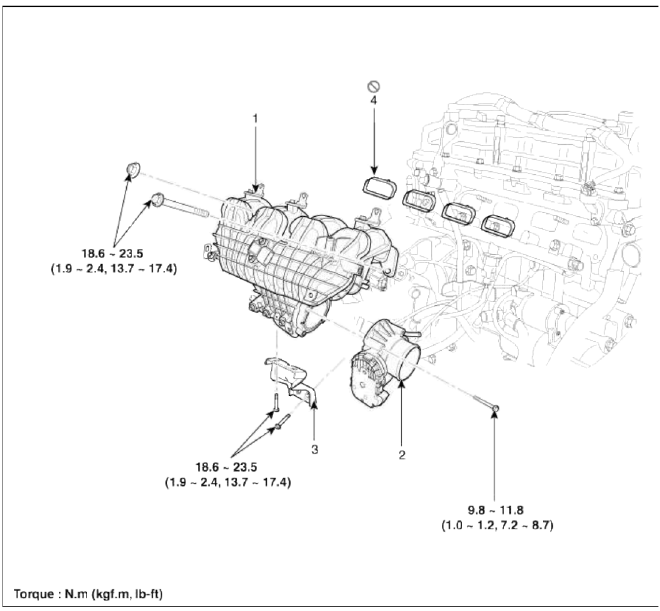

Components

- Intake manifold assembly

- Electronic throttle body

- Intake manifold stay

- Intake manifold gasket

Repair procedures

Removal and Installation

1. Remove the engine cover.

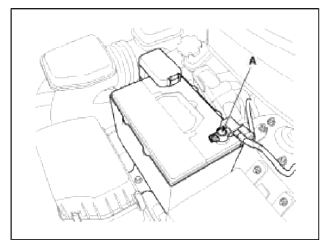

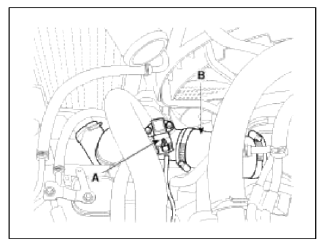

2. Disconnect the battery negative terminal (A).

Tightening torque 4.0 ~ 6.0N.m (0.4 ~ 0.6kgf.m, 3.0 ~ 4.4lb-ft)

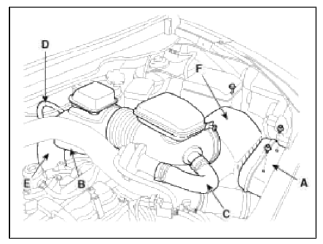

3. Remove the air cleaner assembly.

- Remove the air duct (A).

- Disconnect the breather hose (B), the recirculation hose (C) and brake booster vacuum hose (D).

- Disconnect the air intake hose (E) and then remove the air cleaner assembly (F).

Tightening torque

Hose clamp bolt: 2.9 ~ 4.9N.m (0.3 ~ 0.5kgf.m, 2.2 ~ 3.6lb-ft)

Air cleaner assembly bolts: 7.8 ~ 9.8N.m (0.8 ~ 1.0kgf.m, 5.8 ~ 7.2lb-ft)

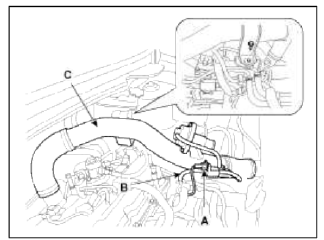

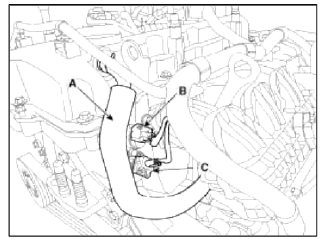

4. Disconnect the recirculation valve connector (A) and the vacuum hose (B), and then remove the intercooler inlet pipe & hose assembly (C).

Tightening torque

Hose clamp bolt: 4.9 ~ 6.9 N.m (0.5 ~ 0.7 kgf.m, 3.6 ~ 5.1 lb-ft)

Pipe mounting bolt: 14.7 ~ 19.6 N.m (1.5 ~ 2.0 kgf.m, 10.8 ~ 14.5 lb-ft)

5. Disconnect the boost pressure sensor connector (A) and then remove the intercooler outlet pipe & hose assembly (B).

Tightening torque 4.9 ~ 6.9 N.m (0.5 ~ 0.7 kgf.m, 3.6 ~ 5.1 lb-ft)

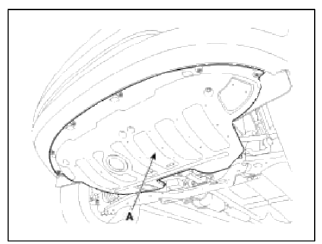

6. Remove the under cover (A).

Tightening torque: 9.8 ~ 11.8 N.m (1.0 ~ 1.2 kgf.m, 7.2 ~ 8.7 lb-ft)

7. Loosen the drain plug, and drain the engine coolant. Remove the radiator cap to drain with speed. (Refer to Cooling system in this group) 8. Disconnect the PCV hose (A), the intake OCV (Oil control valve) connector (B) and the OTS (Oil temperature sensor) connector (C).

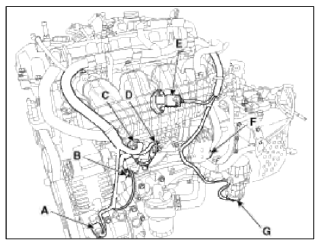

9. Disconnect the Ð/С compressor switch connector (A), the alternator connector (B), the OPS (Oil pressure switch) connector & injector extension connector (C), the knock sensor connector (D), the MAPS (Manifold absolute pressure sensor) & LAPS (Intake air temperature sensor) connector (E), the ETC (Electronic throttle control) connector (F) and the vacuum pump connector (G).

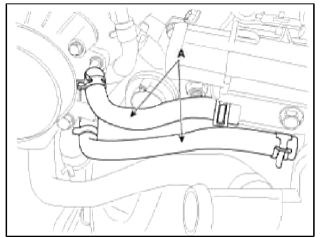

10. Disconnect the throttle body coolant hoses (A).

11. Remove the oil level gauge (A).

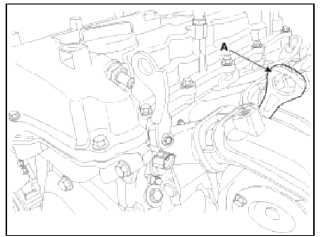

12. Remove the intake manifold stay (A).

Tightening torque: 18.6 ~ 23.5N.m (1.9 ~ 2.4kgf.m, 13.7 ~ 17.4lb-ft)

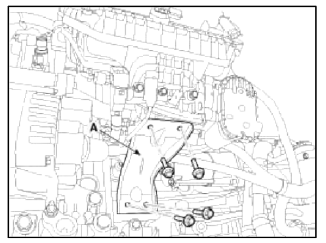

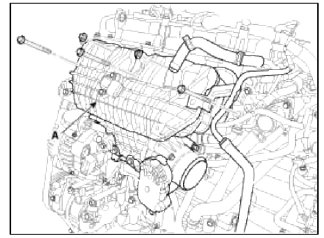

13. Remove the intake manifold (A) after disconnecting the vacuum hoses.

Tightening torque: 18.6 ~ 23.5N.m (1.9 ~ 2.4kgf.m, 13.7 ~ 17.4lb-ft)

NOTE

When installing, replace with new gaskets.

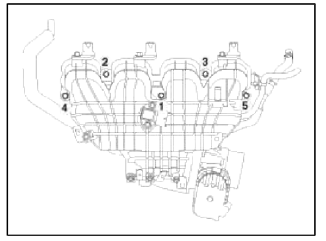

When installing the intake manifold, tighten the bolts and nuts with pre-torque first, and then tighten the bolts and nuts with specified torque in the sequence shown.

14. Installation is reverse order of removal.

READ NEXT:

Exhaust Manifold

Exhaust Manifold

Components and

Components Location

Components

Hear protector

EWGA (Electric Waste Gate

Actuator)

C-ring

Turbo manifold module

Turbocharger stay

Turbo adapter gasket

Turbo a

Turbo Charger

Turbo Charger

Components and

Components Location

Components

Turbine housing

Turbine inlet

Turbine outlet

Compressor housing

Compressor inlet

Compressor outlet

Center housing

EWGA (Electr

Intercooler

Intercooler

Components and

Components Location

Components

Recirculation hose

Intercooler inlet hose & pipe

assembly

Intercooler outlet hose & pipe

assembly

Intercooler mounting bra

SEE MORE:

Power Mosfet | Blower Resistor | Climate Control Air Filter

Power Mosfet | Blower Resistor | Climate Control Air Filter

Repair procedures

Inspection

1. Ignition "ON".

2. Manually operate the control switch and measure the voltage of blower motor.

З. Select the control switch to raise voltage until high speed.

Specification

*AUTO COOLING : Auto speed (4.5V~B+) *AUTO HEATING : Auto speed (4

Torque Converter Control Solenoid Valve (T/CON_VFS) | 26 Brake Control Solenoid Valve (26/B_VFS)

Torque Converter Control Solenoid Valve (T/CON_VFS) | 26 Brake Control Solenoid Valve (26/B_VFS)

Description and Operation

Description

Torque converter control solenoid valve (T/CON_VFS) is attached to the valve body. This variable force solenoid valve directly controls the hydraulic pressure inside the torque converter.

Specifications

Specifications

Direct control VFS [T/CO

Content

- Home

- Kia Sportage - Fifth generation (NQ5) - (2022-2026) - Owner's Manual

- Kia Sportage - Second generation (JEKM) (2005-2015) - Body Workshop Manual

- Kia Sportage Third generation (SL) - (2011-2016) - Service and Repair Manual

- Sitemap

- Top articles