Kia Sportage: Transfer Assembly

Front Wheel Transfer Assembly

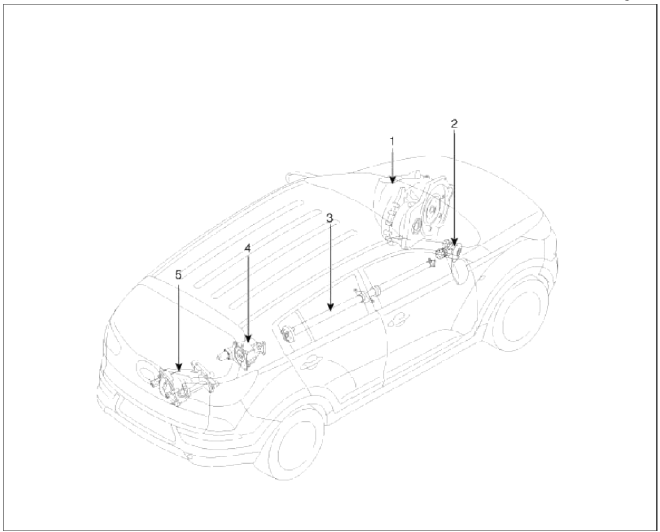

Components and Components Location

Components Location

- Automatic transaxle

- Transfer assembly

- Propeller shaft

- Coupling assembly

- Differential assembly

Repair procedures

Inspection

Transfer Oil Inspection

Transfer oil should be inspected and refilled every 30 months or 37,500 miles.

Transfer Oil Replacement

1. Transfer oil is not replaced in normal condition. But it should be replaced every 75.000 miles in severe driving conditions.

NOTE

Severe driving conditions

- Driving in dusty, rough roads

- Driving in mountains areas

- Driving for patrol car, taxi, commercial car or vehicle towing

- Driving over 170Km/h

CAUTION

Transfer oil should be replaced if the transfer assembly is fall into the water.

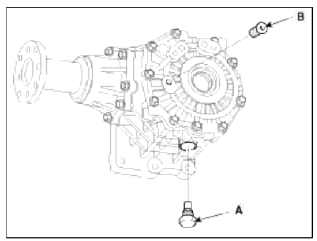

Tightening torque

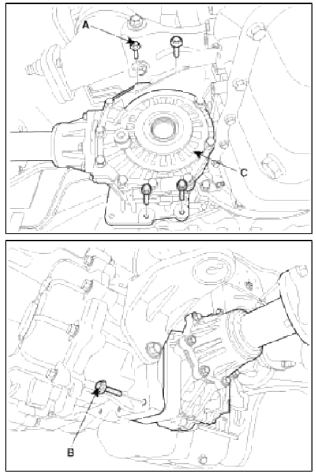

Oil drain plug (A): 39.2 ~ 58.8N.m (4.0~6.0kgf.m, 28.9~43.4lb-ft)

Filler plug (B): 39.2 ~ 58.8N.m (4.0~6.0kgf.m, 28.9~43.4lb-ft

Removal

1. Lift up the vehicle.

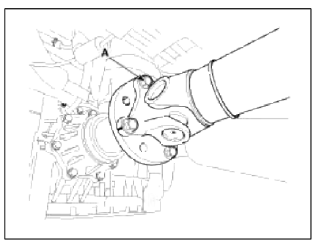

2. Remove the propeller shaft bolts. (A-4ea)

Tightening torque: 49.0~68.6N.m (5.0~7.0kgf.m, 36.2~50.6lb-ft)

3. Remove the right driveshaft (passenger side) from the transfer case. (Refer to "Drive shaft" in DS group).

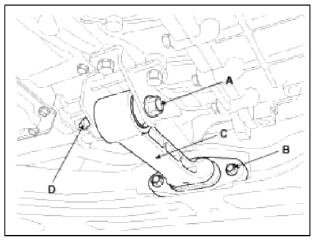

4. Remove the roll rod bracket (C) after removing bolt (A, B).

Tightening torque:

(B) 49.0~63.7N.m (5.0~6.5kgf.m, 36.2~47.0lb-ft)

(D) 107.9~127.5N.m (11~13kgf.m, 79.6~94.1lb-ft)

5. Remove the sub frame. ("Front suspension system" in SS group)

6. Remove the transfer case up and down mounting bolt (A-4ea, B-1ea).

Tightening torque: (A, B) 60.8~65.7N.m (6.2~6.7kgf.m, 44.8~48.5lb-ft)

7. Remove the transfer case (C) with the lever after supporting the transfer case with a jack.

Installation

1. Installation is the reverse of removal.

NOTE

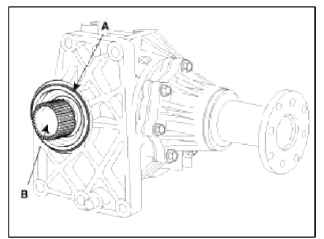

1. Be careful not to damage the О-ring (A). If the О-ring is damaged, replace with a new one.

2. Smear and cover splines (B) with molybdenum type high pressure grease.

TECHLUBE MEGAMAX - ALPHA OR EQUIVALENT

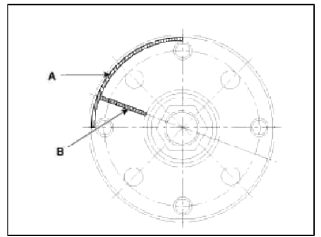

3. Install the propeller shaft near runout marking (Transfer assembly 1ea (A). propeller shaft 1ea (B) ).

READ NEXT:

Description and Operation, Flow Diagram | Schematic Diagrams | Components and Components Location, Repair procedures

Description and Operation, Flow Diagram | Schematic Diagrams | Components and Components Location, Repair procedures

Description and Operation

Description

4WD ECU processes signals from various sensors and determines the current road and driving conditions. The ECU then utilizes this information to impleme

SEE MORE:

Operating door locks from inside the vehicle

Operating door locks from inside the vehicle

You can operate door locks with the

door lock handle or central door lock

switch.

With the door handle

Front door

If the inner door handle is pulled when

the door is locked, the door will unlock

and open.

Rear door

If the inner door handle is pulled once

when the door is locked

How to reset the power liftgate

How to reset the power liftgate

If the battery has been discharged or

disconnected, or if the related fuse has

been replaced or disconnected, for the

power liftgate to operate normally, reset

the power liftgate as follow:

Make sure the gear is shifted to P

(Park) position.

Press and hold the Power liftgate

open/close

Content

- Home

- Kia Sportage - Fifth generation (NQ5) - (2022-2026) - Owner's Manual

- Kia Sportage - Second generation (JEKM) (2005-2015) - Body Workshop Manual

- Kia Sportage Third generation (SL) - (2011-2016) - Service and Repair Manual

- Sitemap

- Top articles