Kia Sportage: SS-B Solenoid Valve (ON/OFF)

Description and Operation

Description

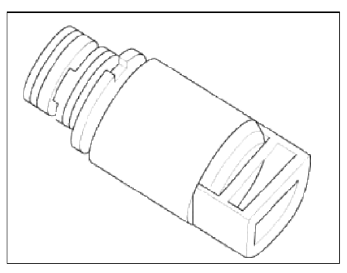

SS-B solenoid valve is attached to the valve body and is an on/off solenoid valve that is used to change gears. SS-B Solenoid valve (ON/OFF) is installed at valve body.

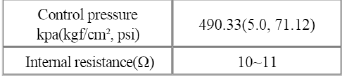

Specifications

Specifications

ON/OFF Solenoid Valve (SS-A, SS-B)

Control type : Normal low type

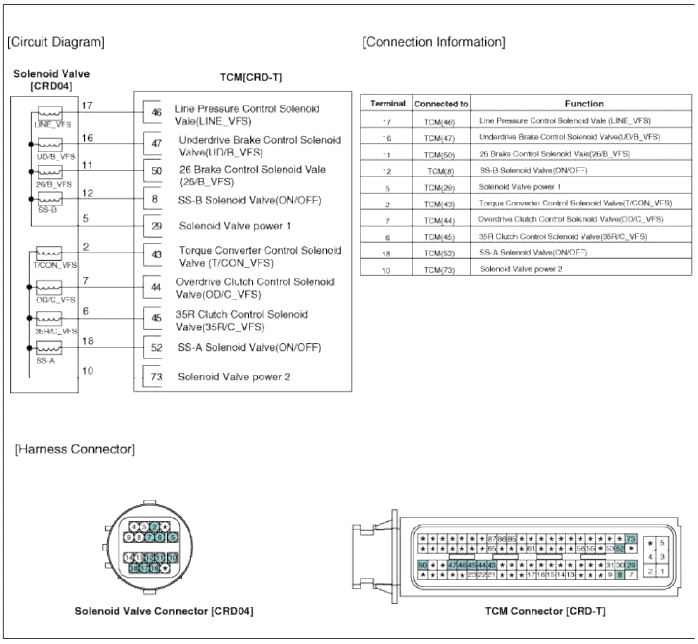

Schematic Diagrams

Circuit Diagram

Repair procedures

Inspection

1. Turn ignition switch OFF.

2. Disconnect the oil temperature sensor connector.

3. Measure resistance between sensor signal terminal and sensor ground terminal.

4. Check that the resistance is within the specification.

Removal

NOTE

Replacing an on/off solenoid valve (SS-A, SS-B) does not requite additional hydraulic pressure adjustment; however, the hydraulic pressure will need to be adjusted after replacing the VFS solenoid valve. If replacing the VFS solenoid valve; also replace the valve body assembly. (Refer to "Valve Body" in this group)

1. Remove the battery and the battery tray. (Refer to "Charging system" in EE group.)

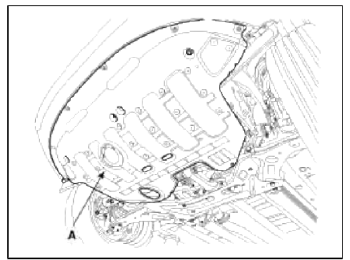

2. Remove the under cover (A).

Tightening torque: 19.6 ~ 24.5 N.m (2.0 ~ 2.5 kgf.m, 14.5 ~ 18.1 lb-ft)

3. Replace new gasket and the plug after draining the automatic transaxle fluid by removing the drain plug. (Refer to "Hydraulic system (Fluid)" in this group)

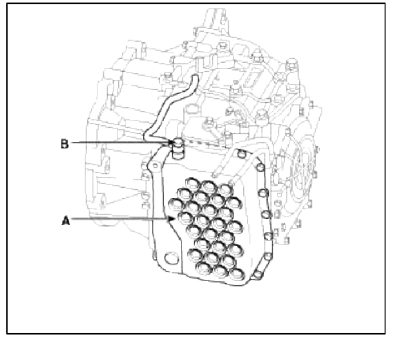

4. Remove the valve body cover (A) and eyebolt (B).

Tightening torque:

(A) 13.8 ~ 14.7 N.m (1.3 ~ 1.5 kgf.m, 9.4 ~ 10.8 lb-ft)

(B) 34.3 ~ 44.1 N.m (3.5 ~ 4.5 kgf.m, 25.3 ~ 32.6 lb-ft)

CAUTION

Always replace the gasket of the eyebolt use new one whenever loosening eyebolt.

NOTE

Remove installation bolts in the engin room first and then remove others under the vehicle.

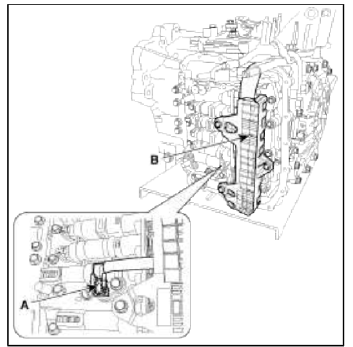

5. Remove the bolt (3ea) after disconnecting the solenoid valve connector (B) and the oil temperature sensor connector (A).

Tightening torque: 9.8 ~ 11.8 N.m (1.0 ~ 1.2 kgf.m, 7.2 ~ 8.7 lb-ft)

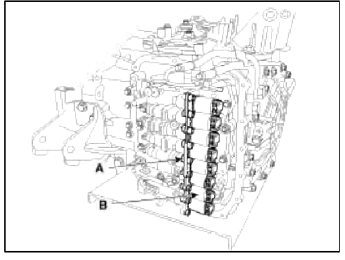

6. Remove the solenoid valve (B) after removing the solenoid support (A).

Installation

1. Installation is the reverse of removal.

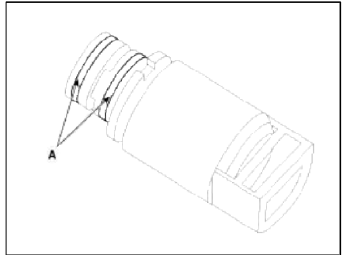

NOTE

- When installing, apply the ATF oil or white vaseline to the O-ring (A) not to be damaged.

- Continue to apply liquid gasket at application points at the valve body cover with Ø2.5mm (0.0984in.) thickness.

Liquid gasket Part name : Threebond 1281B or LOCTITE FMD-546

- Adding automatic transaxle fluid. (Refer to "Hydraulic system (Fluid)" in this group)

READ NEXT:

Inhibitor Switch

Inhibitor Switch

Description and Operation

Description

Inhibitor Switch monitors the lever's position (PRXD) and is used to control

gear setting signals.

Specifications

Specifications

Type: Co

Shift Lever

Shift Lever

Components and Components Location

Components

Shift lever knob & boots

assembly

Shift lever assembly

Control cable assembly

Manual control lever (T/M side)

Repair procedure

SEE MORE:

Fender panel & Hood panel & Tail gate panel

Fender panel & Hood panel & Tail gate panel

Hood panel assembly

Hood hinge assembly

Fender panel

Tail gate panel assembly

Tail gate hinge assembly

Door panel

Front door panel assembly

Rear door panel assembly

Front door hinge assembly

Rear door hinge assembly

Starter Relay

Starter Relay

Repair procedures

Inspection

1. Remove the fuse box cover.

2. Remove the starter relay (A).

3. Using an ohmmeter, check that there is continuity between each terminal.

4. Apply 12V to terminal 85 and ground to terminal 86.

Check for continuity between terminals 30 and 87.

5. If ther

Content

- Home

- Kia Sportage - Fifth generation (NQ5) - (2022-2026) - Owner's Manual

- Kia Sportage - Second generation (JEKM) (2005-2015) - Body Workshop Manual

- Kia Sportage Third generation (SL) - (2011-2016) - Service and Repair Manual

- Sitemap

- Top articles