Kia Sportage: Components and ComponentsLocation | Disassembly - Repair procedures

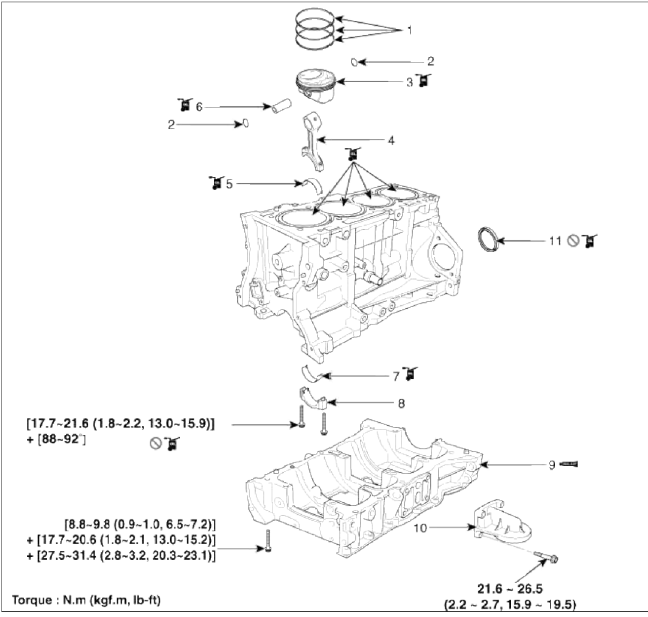

Components

- Piston ring

- Snap ring

- Piston

- Connecting rod

- Connecting rod upper bearing

- Piston pin

- Connecting rod lower bearing

- Connecting rod bearing cap

- Ladder frame

- Oil filter bracket

- Crankshaft rear oil seal

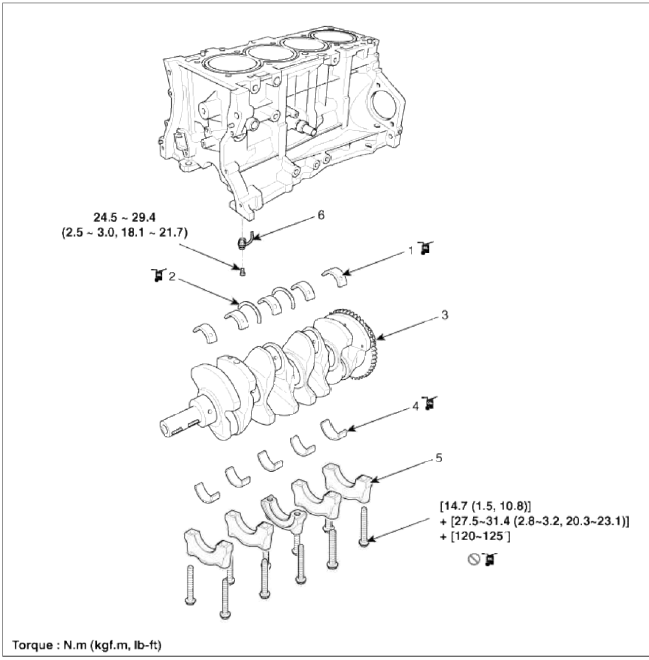

- Crankshaft upper bearing

- Thrust bearing

- Crankshaft

- Crankshaft lower bearing

- Main bearing cap

- Piston cooling oil jet

Disassembly - Repair procedures

CAUTION

- Use fender covers to avoid damaging painted surfaces.

- To avoid damage, unplug the wiring connectors carefully while holding the connector portion.

NOTE

- Mark all wiring and hoses to avoid misconnection.

- Turn the crankshaft pulley so that the No.1 piston is at top dead center.

- Engine removal is required for this procedure.

WARNING

In case of removing the high pressure fuel pump, high pressure fuel pipe, delivery pipe, and injector, there may be injury caused by leakage of the high pressure fuel. So don't do any repair work right after engine stops.

1. Remove the engine assembly from the vehicle. (Refer to Engine and transaxle assembly in this group)

2. Install the engine to an engine stand for disassembly.

3. Remove the intake manifold and exhaust manifold. (Refer to Intake and exhaust system in this group)

4. Remove the timing chain. (Refer to Timing system in this group)

5. Remove the cylinder head assembly. (Refer to Cylinder head in this group)

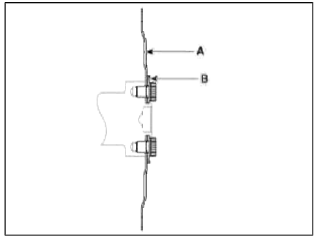

6. Remove the drive plate (A) and the adapter plate (B).

7. Remove the balance shaft & oil pump assembly. (Refer to Lubrication system in this group)

8. Remove the Ð/С compressor. (Refer to HA group)

9. Remove the alternator. (Refer to EE group)

10. Remove the water pump assembly. (Refer to Cooling system in this group)

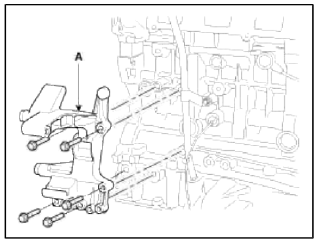

11. Remove the tensioner assembly integrated bracket (A).

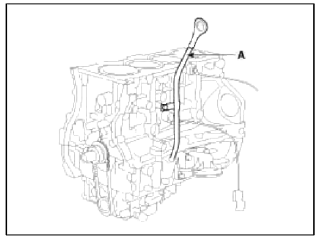

12. Remove the oil level gauge tube (A).

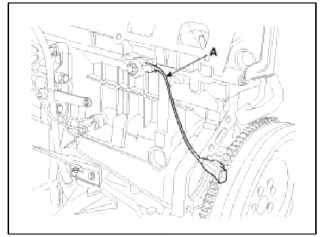

13. Remove the knock sensor (A).

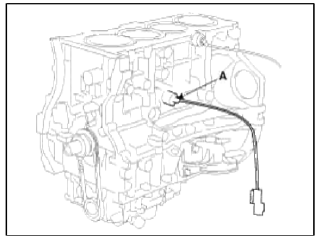

14. Remove the oil pressure sensor (A).

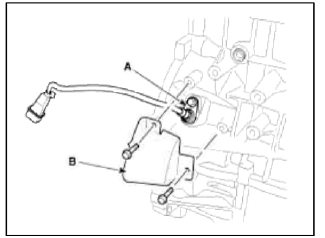

15. Remove the cover (B) and then CKPS (Crankshaft position sensor) (A).

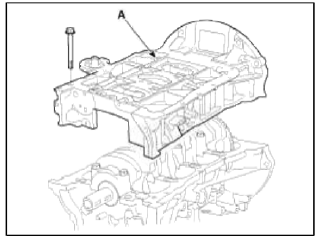

16. Remove the ladder frame (A).

17. Check the connecting rod end play.

18. Remove the connecting rod caps and check oil clearance.

19. Remove piston and connecting rod assemblies.

- Using a ridge reamer, remove all the car bon from the top of the cylinder.

- Push the piston, connecting rod assembly and upper bearing though the top of the cylinder block.

NOTE

- Keep the bearings, connecting rod and cap together.

- Arrange the piston and connecting rod assemblies in the correct order.

20. Remove crankshaft bearing cap and check oil clearance.

21. Check the crankshaft end play.

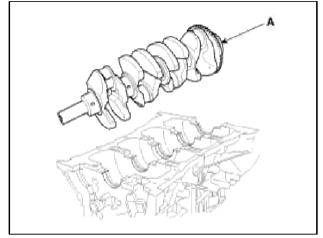

22. Lift the crankshaft (A) out of the engine, being careful not to damage journals.

NOTE

Arrange the main bearings and thrust bearings in the correct order.

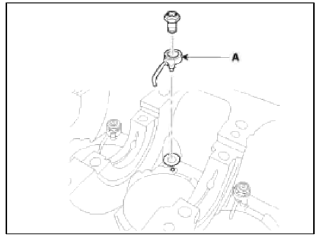

23. Remove the oil jet (A).

24. Check fit between piston and piston pin.

Try to move the piston back and forth on the piston pin. If any movement is felt, replace the piston and pin as a set.

25. Remove piston lings.

- Using a piston ring expander, remove the 2 compression lings.

- Remove oil ring.

NOTE

Arrange the piston rings in the correct order only.

26. Disconnect connecting rod from piston.

Remove the snap ring at both ends of piston pin. And push the piston pin to seperate and connecting rod.

READ NEXT:

Inspection - Repair procedures

Inspection - Repair procedures

Connecting Rod

1. Check the connecting rod end play.

Using a feeler gauge, measure the end play while moving the connecting rod back

and forth.

End play:

Standard : 0.10 ~ 0.25mm (0.0039 ~ 0.0

Reassembly - Repair procedures

Reassembly - Repair procedures

NOTE

Thoroughly clean all parts to assembled.

Before installing the parts, apply fresh engine oil to all sliding

and rotating surfaces.

Replace all gaskets, O-rings and oil seals with new p

SEE MORE:

Troubleshooting

Troubleshooting

Failure Diagnosis

1. In principle, ESC and TCS controls are prohibited in case of ABS failure.

2. When ESC or TCS fails, only the failed system control is prohibited.

3. The solenoid valve relay should be turned off in case of ESC failure, refer

to the ABS fail-safe.

4. Information on AB

Direct Electro Hydraulic Actuator Coupling

Direct Electro Hydraulic Actuator Coupling

Description and Operation

Description

4WD ECU processes signals from various sensors and determines the current

road and driving conditions. The ECU then

utilizes this information to implement precision control over the 4WD coupling's

multi-plate clutch and variably adjust the

amou

Content

- Home

- Kia Sportage - Fifth generation (NQ5) - (2022-2026) - Owner's Manual

- Kia Sportage - Second generation (JEKM) (2005-2015) - Body Workshop Manual

- Kia Sportage Third generation (SL) - (2011-2016) - Service and Repair Manual

- Sitemap

- Top articles