Kia Sportage: Preparation of assembly

Kia Sportage - Second generation (JEKM) (2005-2015) - Body Workshop Manual / General information / For best results / Preparation of assembly

Applying spot sealer

Remove paint from the surface of new parts and body to be spot welded, and apply spot sealer for rustproofing.

Selecting a welding method

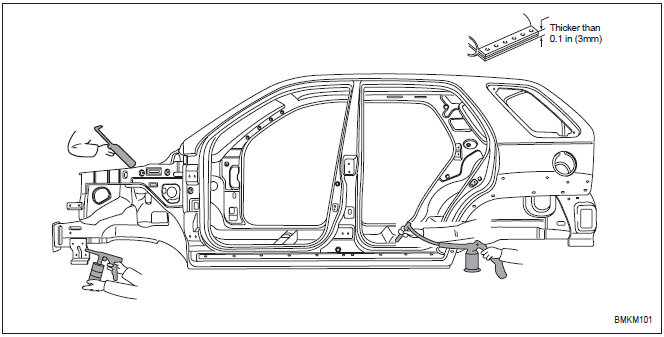

If the thickness of the area to be welded with the panels overlapped is greater than 0.1 in (3 mm), do plug welding using a carbon arc welding machine.

Machining holes for plug welding

Drill a hole of approximately 0.2~0.24 in (5~6 mm) in diameter in those areas which are not suitable for spot welding.

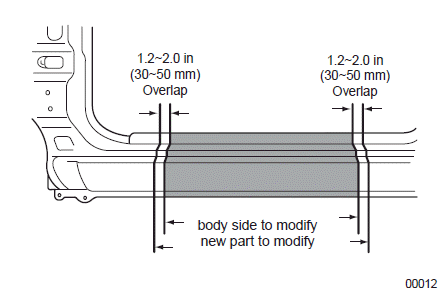

Adjusting a new part

The new part should be cut larger than the repair area, overlapping the repair area by 1.2~2.0 in (30~50 mm).

READ NEXT:

Assembly

Assembly

Measuring dimensions before welding

When assembling a new part, assemble it according to the body dimensions

given in Section 31, and start welding

after checking the gaps with nearby parts.

Caut

Rustproof treatment after assembly

Rustproof treatment after assembly

Body sealing

Apply body sealer where necessary.

Applying rustproof material

Apply rustproofing material (wax, oil, etc.) behind welded area.

Applying undercoat

Apply undercoat on the body where

Vehicle lift (2-Support type) and safety stand positions

Vehicle lift (2-Support type) and safety stand positions

1. Place the lift blocks under the support points as shown in the

illustration.

2. Raise the hoist a few inches and rock the vehicle to be sure it is firmly

supported.

3. Raise the hoist to fu

SEE MORE:

Cleaning the upholstery and interior

trim

Cleaning the upholstery and interior

trim

Car interior surfaces

Remove dust and loose dirt from interior

surfaces with a whisk broom or a vacuum

cleaner. If necessary, clean interior

surfaces with a mixture of warm water

and mild non-detergent cleaner (test all

cleaners on a concealed area before

use).

Fabric

Remove dust and loose

Warning Control

Warning Control

Warning Control

1. The Warning function offers the following features

Seat Belt Warning

Seat Belt Re minder

Over Speed Warning

Key Reminder Warning

Parking Brake Warning

RKE Key Teaching sound

SMK System Warning

RAPS Warning

Rheostat Detent Warning

2. Buzzer Operation

Content

- Home

- Kia Sportage - Fifth generation (NQ5) - (2022-2026) - Owner's Manual

- Kia Sportage - Second generation (JEKM) (2005-2015) - Body Workshop Manual

- Kia Sportage Third generation (SL) - (2011-2016) - Service and Repair Manual

- Sitemap

- Top articles